Analysts and supply chain practitioners have been discussing the concepts of a demand-driven supply chain (DDSC) for a decade. We have been working with our customers across many different industries, to help them realize these concepts. What is fascinating and revealing is how the core concepts are manifested in different ways depending on industry characteristics.

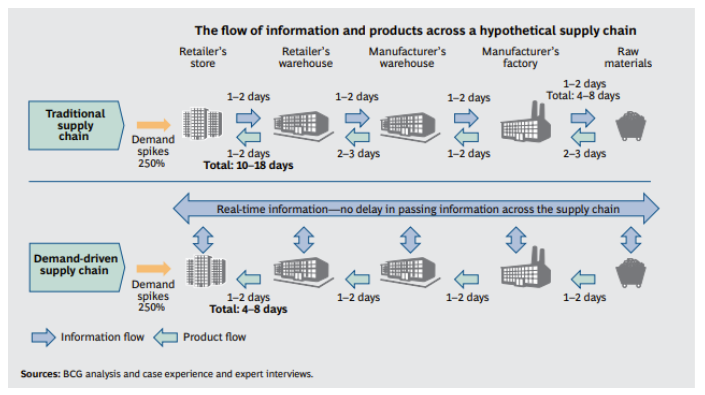

First, let’s get to a common definition of DDSC. The original impetus for DDSC was to understand the impact of latency and aggregation as information propagates up the supply chain from the source of demand to the suppliers, i.e., the bullwhip effect. Given typical supply lead times, suppliers generally produce enough to meet the demand forecast, which is only marginally accurate at the granular level at which inventory decisions (SKU/week) are made. However, as soon as it is known that the actual demand differs from the forecast, the supply levels need to be adjusted accordingly at each step of the supply chain. But due to the lag time between when the demand changes and when it is detected at various points along the supply chain, its effect is often amplified, leading to inventory shortages or excesses.

Companies tend to overcompensate by slowing down or speeding up production, which can cause inventory levels to fluctuate. This whipsaw effect is costly and inefficient for all participants.

Several important supply chain concepts have emerged in order to mitigate the bullwhip effect. These concepts are collectively referred to as “demand driven supply chain” and can be organized in terms of “demand side” and supply side” initiatives.

Demand-side initiatives focus on better ways to capture the demand signal closer to the source, analyze the demand to sense the latest and most accurate demand signal, and shape the demand by executing and tracking promotional and pricing strategies to steer demand in line with business objectives.

Supply-side initiatives generally have to do with lessening reliance on the forecast, by becoming more agile with faster response, when actual demand is known.

All of these strategies are aspects of being demand-driven, but it is rare to see a company pursue all of them. In fact, we have come to understand that, depending on the characteristics of the market and industry, companies will emphasize different elements. In this article we will look at the consumer packaged goods (CPG) and high-technology industries to illustrate this point.

The supply chain landscape has transformed drastically over the past few decades. With the onset of advanced technologies like the Internet of Things (IoT), e-commerce, and shifting consumer preferences, meeting demand has become increasingly challenging for suppliers and manufacturers. Often, demand changes rapidly, while supply struggles to keep up. This causes shortages, backlogs, and dissatisfied customers.

To overcome these challenges, leading companies are adopting a demand-driven approach to supply chain management. But what exactly does “demand-driven supply chain” mean? In this comprehensive guide, we’ll demystify the demand-driven model and show you how to implement it successfully.

What is a Demand-Driven Supply Chain?

A demand-driven supply chain uses actual customer demand to drive all supply chain decisions and activities. It is a pull-based model, where downstream customers pull products and materials upstream as needed. This is contrasted with a forecast-driven “push” model, where companies try to predict demand and push products out based on forecasts.

In a demand-driven model, companies constantly monitor real-time point-of-sale (POS) data, orders, inventory levels, and other demand signals As demand fluctuations occur, this information flows upstream to suppliers in real-time so production and fulfillment can adapt quickly. The goal is to maintain just enough inventory to meet real demand, avoiding shortages, excesses, and costs

Key Characteristics of a Demand-Driven Supply Chain

To be truly demand-driven a supply chain should have these essential elements

-

Demand sensing – The ability to track real-time demand signals and changes from numerous sources including POS, inventory orders, promotions, and more. This provides the critical input for driving supply chain activities.

-

Pull-based supply – Inventory and materials are “pulled” upstream only as needed to fill real orders and demand. Nothing is produced speculatively. This prevents excess inventory build-up.

-

Rapid orchestration – With demand visibility, companies can quickly adjust production, inventory, transportation, labor, and other supply chain resources to meet fluctuations. Changes can be coordinated in real-time across the extended supply chain.

-

Enterprise alignment – All departments (sales, marketing, finance, production, procurement, etc.) have shared goals, metrics, and plans driven by actual demand data. Information is visible enterprise-wide.

-

Supply chain segmentation – Different inventory policies and supply chain processes for each product line or channel matched to actual demand profiles and fluctuations of that segment.

The Benefits of Shifting to a Demand-Driven Model

Companies who have implemented demand-driven supply chains report numerous benefits, including:

-

Higher service levels – Inventory is aligned with true demand, reducing stockouts and improving order fill rates.

-

Lower inventories – No excess or obsolete stock since inventory mirrors actual demand. Reduces working capital needs.

-

Improved responsiveness – Production and fulfillment adapt quicker to demand shifts based on real-time data.

-

Greater agility – Enter new markets, launch products faster, and meet spikes in demand more easily.

-

Lower costs – Reduce supply chain waste and inefficiencies by aligning activities with real needs.

According to Gartner, demand-driven leaders achieve supply chain costs that are 35% lower than the average company. Implementing demand-driven principles also boosts corporate revenues on average by 9.5%.

How to Make the Shift to Demand-Driven Supply Chains

Transitioning from forecast-based to demand-driven supply chain requires strategic changes across people, processes, and technology:

Install demand sensing technology – The starting point is implementing scalable technology to collect, cleanse, and analyze real-time demand data from all customer touchpoints. This provides the visibility to respond quickly.

Increase supply chain flexibility – Assess production, distribution, and supplier networks to determine where to build in flexibility through methods like multi-sourcing, postponement, modular design, and alternate transportation modes.

Develop demand-driven sales & operations planning (S&OP) – Integrate financial planning, demand planning, inventory planning, and sales & marketing around a demand-centric S&OP process. This aligns the organization.

Adopt pull-based inventory policies – Use pull-based reorder point, kanban, or optimization algorithms for inventory management rather than traditional order point / order quantity. Pull only what demand requires.

Retrain planners – Help planners transition from forecast-driven push techniques to leveraging demand signals, monitoring trends, and orchestrating supply to actual requirements.

Incentivize collaboration – Break down functional silos by incentivizing teams to achieve shared demand-driven metrics like inventory turns, fill rates, and responsiveness.

Start small – Introduce demand-driven practices in one region or product line to prove effectiveness before expanding organically across the network.

Demand-Driven Supply Chains In Action

Leading companies who have re-architected their supply chains around demand achieve impressive results:

-

Lenovo cut average inventory days by over 50% while improving order fill rates and customer satisfaction scores.

-

Schneider Electric accelerated cash flow by $200 million annually after implementing demand-driven S&OP and inventory optimization.

-

Cummins reduced supply chain costs by 20% and improved order fill rates to over 95% with better demand visibility.

-

Lowe’s boosted inventory turns by 30% after shifting to a demand-driven model across its network.

These examples demonstrate the power of aligning supply around actual customer demand. While it requires changes in technology, metrics, and mindsets, the payoff in responsiveness, working capital efficiency, and customer service make it well worth the investment.

Final Thoughts

With today’s consumer-driven economy and digital disruptions, demand volatility is only rising. Companies must re-engineer their supply chains to thrive amidst this turbulence. A demand-driven model provides the visibility and agility to continuously align supply with demand in a profitable and efficient manner.

By implementing the principles outlined here, you can position your company for success both today and tomorrow. The supply chain landscape will keep evolving – make sure your business has the resilience and responsiveness to stay ahead of the changes.

DDSC in Consumer Packaged Goods

CPG companies strive to achieve very high service levels—consumers typically do not wait if their preferred product is not on the shelf; they instead go elsewhere or choose a competitor’s product. Furthermore, CPG companies are typically not supply constrained—they determine what inventory levels they need, and they set capacity and/or prebuild stocks in order to have the required inventory. Therefore, it is not surprising that we see an emphasis in CPG on demand-side strategies, although this is starting to change.

Traditionally, CPG companies have forecast demand based on distribution center (DC) shipments to retailers/wholesalers. These processes mask actual consumer behavior, and add days if not weeks of latency to the information flow. There have been a number of initiatives that have been adopted by the industry to remedy this:

• The most common demand-side initiative, which has been in use for over two decades, is a customer collaboration replenishment strategy. This includes techniques such as vendor-managed inventory (VMI) and collaborative planning, forecasting and replenishment (CPFR). Such techniques allow CPG manufacturers to get closer to the demand signal by gaining visibility to retailer inventory, forecasts and shipments from DCs to stores. Such initiatives have and continue to deliver significant value in terms of reducing inventory and enhancing service.

• Over the past 10-20 years, CPG companies have started to go a step further. By tapping into point-of-sale (POS) data directly from the retailer, CPG companies can get clear visibility into actual demand, rather than using distribution center shipments as a proxy. Such clear visibility allows CPG manufacturers to see what consumers are actually buying, with minimum latency, allowing them to adjust their supply plans quickly and accurately.

• Furthermore, by modeling demand characteristics such as order volume over time, and correlations of what products sell together, CPG companies are able to understand demand patterns to enhance short term forecasts (demand sensing). In these demand sensing applications, the emphasis is on separating and analyzing both the normal demand flow, as well as any incremental promotional lift. Demand modeling also allows CPG manufacturers to work with retailers to optimize merchandising strategies

• Access to POS data is also used by CPG marketing teams to better understand the correlation between promotional strategies they deployed and resulting change in sales volume. These activities provide them the insights they need to increase the effectiveness of their promotions and pricing actions. Armed with actual impact on sales from promotional pricing, CPG companies are better equipped to deploy demand shaping strategies that work.

• Point-of-sale information capture also allows CPG companies to gain better visibility into where the downstream inventory is: at the retailer’s DC, in the store back room, or on the shelf, and allows them to infer out-of-stock conditions. Such information is not only useful as a real-time alert to trigger replenishment, but also allows them to collaborate with retailers in measuring and improving sales execution.

In CPG, on the supply side, the emphasis has been historically on fast and frequent replenishment processes, either based on VMI or using deployment algorithms leveraging the enhanced demand signals described above. Fast replenishment is especially critical during promotional periods, when out-of-stock situations not only result in lost sales, but in potential impact to customer loyalty.

Trends are now emerging which are putting further pressure on CPG manufacturers to adopt more advanced supply-side initiatives. In many markets, retailers are also optimizing their own supply networks and expecting more from CPG manufacturers. Penalties are imposed on manufacturers who do not meet fulfillment targets and these penalties have grown substantially across the industry. In many markets, CPG companies are receiving ever growing percentages of orders (via EDI) that require same-day shipment. Lastly, in certain CPG segments (such as cosmetics), high-margin products with short lifecycles are becoming more common.

To adapt to these trends, we are seeing CGP companies striving to speed up/postpone their planning and fulfillment processes, shorten lead times, wait longer to capture the same-day demand before pulling the replanning/replenishment trigger.

While many high-tech companies (especially in consumer electronics) face some of the demand-side challenges described above, there are significant differences in the supply chain of these companies that leads to very different strategies for becoming demand-driven.

Many high-tech companies operate in a context of high market uncertainties due to short product lifecycles. Given these short lifecycles, such companies must be careful in building finished goods inventories, or face massive write-off costs. Often these supply chains strive to keep as much stock as possible as components or in a semi-finished product stage, and postpone final assembly. In many cases, critical components that go into the product are in short supply, requiring allocations.

Most often these components also have long lead time items from offshore suppliers. Furthermore, for many high-tech companies, demand originates from multiple channels, including retail, corporate/industrial and direct consumer. The combination of these issues makes DDSC dynamics different in the high-tech industry:

• Demand-driven strategies in the high-tech industry start with product design, where companies strive to use a common product platform in their engineering designs, so they can maximize the use of standard components and aggregate capacity. This strategy enables them to delay the final SKU configuration until the demand is better established.

• High-tech companies have made great strides in reducing the planning cycles and increasing planning frequencies to become more responsive. Given the demand volatility due to e-commerce models and continuous competitor leapfrogging, it is not uncommon to see weekly tactical (S&OP) planning cycles with daily and even sub-daily updates.

• With different go-to-market channels, demand-driven is not just about finished goods inventory. In many cases, high-tech companies implement build-to-order or configure-to-order strategies, where they forecast at the level of options or subassemblies that they require. This leads to collaborative planning processes, where the forecast is sent to suppliers and contract manufacturers for their commitment, and then a constrained plan is agreed-to and locked in.

• When the plan is constrained, companies are driven to allocate their supply to various demand channels and priorities in order to protect their strategic goals, and their key accounts. As a result, advanced demand prioritization methods are used to plan what demand will be fulfilled, and to enforce these allocation decisions as orders are received and fulfilled. In such scenarios, it is critical that once supply commitments are made, it is possible to re-plan to capture tomorrow’s demand, while still protecting the prior commitments for strategically important accounts. Such rules-based advanced commitment management processes are a central element of a high-tech demand-driven supply chain.

• Even though the supply chain plan is “locked in,” it must respond to demand changes. This is a key challenge in engineering the high-tech segment’s demand-driven supply chain. Hence, companies are implementing collaboration processes to achieve upstream visibility to material and capacity situations, and developing simulation-based what-if replanning scenarios (often called “shadow planning”) to be able to quickly determine if a plan change is feasible and desirable.

• Lastly, we are seeing some companies adopt the ultimate demand-driven supply initiative—consumption-based pull planning. In this scenario, inventory buffers are placed at critical points in the supply chain to decouple processes and minimize lead times, and supply actions (deployment, production and procurement) are triggered by consumption-based replenishment. This affords protection against demand uncertainty by only building to a replenishment signal, not to a forecast.

The chart below offers a summary of how CPG and high-tech companies are adopting demand-side and supply-side strategies for becoming demand-driven.

Demand-Driven Supply Chain 2.0

What is a demand-driven supply chain?

Demand-driven supply chains examine many factors, like trends and online consumer activity, to adjust forecasting in real time. By reducing the time it takes to learn about changes in demand, companies can react more quickly to market fluctuations and alter their operations to meet those changes. Another important DDSC element is technology.

What is the difference between demand-driven and traditional supply chain methods?

The demand-driven market tends to have greater elasticity – compared to traditional supply chain methods. For example, the prices in a demand-driven market respond to any changes in demand whereas the opposite reacts to changes in supply. So, demand-driven is demanded by the customers while traditional methods are primarily determined by suppliers.

What is a demand-driven supply network (DDSN)?

A Demand-driven supply network (DDSN) is one method of supply-chain management which involves building supply chains in response to demand signals. The main force of DDSN is that it is driven by customers demand. In comparison with the traditional supply chain, DDSN uses the pull technique.

What makes a supply chain more demand-driven?

Companies have invested huge amounts in making their supply chains more demand-driven. However, these efforts are typically confined to one geography, one business unit and/or one function, such as procurement, planning, logistics or inventory management.