Companies rely on solid processes to efficiently and effectively meet objectives. But without strong processes, your business could be losing money, talent, and even clients.

Studying your current state helps organizations document, track, and optimize processes for better performance, greater efficiency, and improved outcomes.Â

Hereâs how you can take your business to the next level by documenting your as-is process. Business process flow template (click on to modify online)

An As-is Process Flow is a process management strategy that documents how business processes are currently implemented. Usually an As-is Process flow is made for companies to track procedures that are organized step by step. This process flow can later be analyzed and optimized when the business creates a To-Be Process.

Process mapping is an indispensable technique used by organizations across all industries to visualize, analyze, and optimize their business processes. But before an organization can improve its processes, it must first understand how its processes currently operate. This is where AS-IS process mapping comes in.

In this comprehensive guide, we will cover everything you need to know about AS-IS process mapping, including:

- What is AS-IS process mapping

- The benefits of AS-IS process mapping

- How to create an AS-IS process map

- Tips for effective AS-IS process mapping

- The role of AS-IS maps in continuous process improvement

What Exactly is AS-IS Process Mapping?

AS-IS process mapping, also referred to as “current state mapping”, involves documenting and visually representing an organization’s existing processes and workflows exactly as they are executed currently The goal is to capture an accurate snapshot of how work gets done presently within the organization.

In essence, AS-IS process maps showcase the current state of an organization’s operations, procedures, and activities. They provide visibility into

- The steps involved in each process

- The sequence in which those steps occur

- The movement of information and materials through each process

- The roles, systems, and departments involved at each step

AS-IS process maps serve as the baseline for analyzing and enhancing operations within an organization. Without understanding the current state it is challenging to identify areas for improvement and growth.

Why is AS-IS Process Mapping Important?

Here are some of the key benefits that organizations can gain from AS-IS process mapping:

-

Understanding the current state – It offers an objective, fact-based view of existing processes rather than assumptions. This understanding is fundamental for process enhancement initiatives.

-

Identifying inefficiencies – Inefficiencies such as bottlenecks, redundancies, delays, and unnecessary steps are easily identifiable in a process map.

-

Facilitating communication – AS-IS maps provide a common language and point of reference for teams to discuss pain points and future process requirements.

-

Training employees – The maps serve as useful training tools for new hires to gain an overview of processes.

-

Basis of process redesign – AS-IS maps serve as the starting point for developing improved processes that are more efficient, effective and aligned with business objectives.

-

Conforming to standards – Certain standards and regulations require organizations to document their AS-IS processes, such as ISO 9001.

Clearly, AS-IS process mapping delivers immense value. It sets the stage for process excellence by enhancing understanding, accountability, and transparency.

How to Create an AS-IS Process Map: Step-By-Step

Here is a step-by-step guide to creating an effective AS-IS process map:

Step 1: Define the Process Scope

First, clearly define the scope and boundaries of the process you want to map. Try to focus on mapping one coherent process at a time. Defining the scope ensures your map will be concise and focused.

Step 2: Gather Information

Next, gather detailed information about the process. Useful sources include:

- Documents – Standard operating procedures, work instructions, flowcharts, etc.

- Employees – Interview process owners and employees directly involved in executing the process.

- Observations – Observe the process in real-time to identify undocumented practices.

Step 3: Identify Process Elements

Identify the key elements to be captured in the map, including:

- All process steps from start to finish

- Decision points and branching logic

- Roles, departments, and systems involved

- Inputs required and outputs generated

- Process performance metrics like cycle time

Step 4: Choose a Mapping Notation

Select a process mapping notation like flowcharts, SIPOC diagrams, swimlane diagrams, or BPMN. Choose a method apt for the process complexity and the intended audience.

Step 5: Create the Process Map

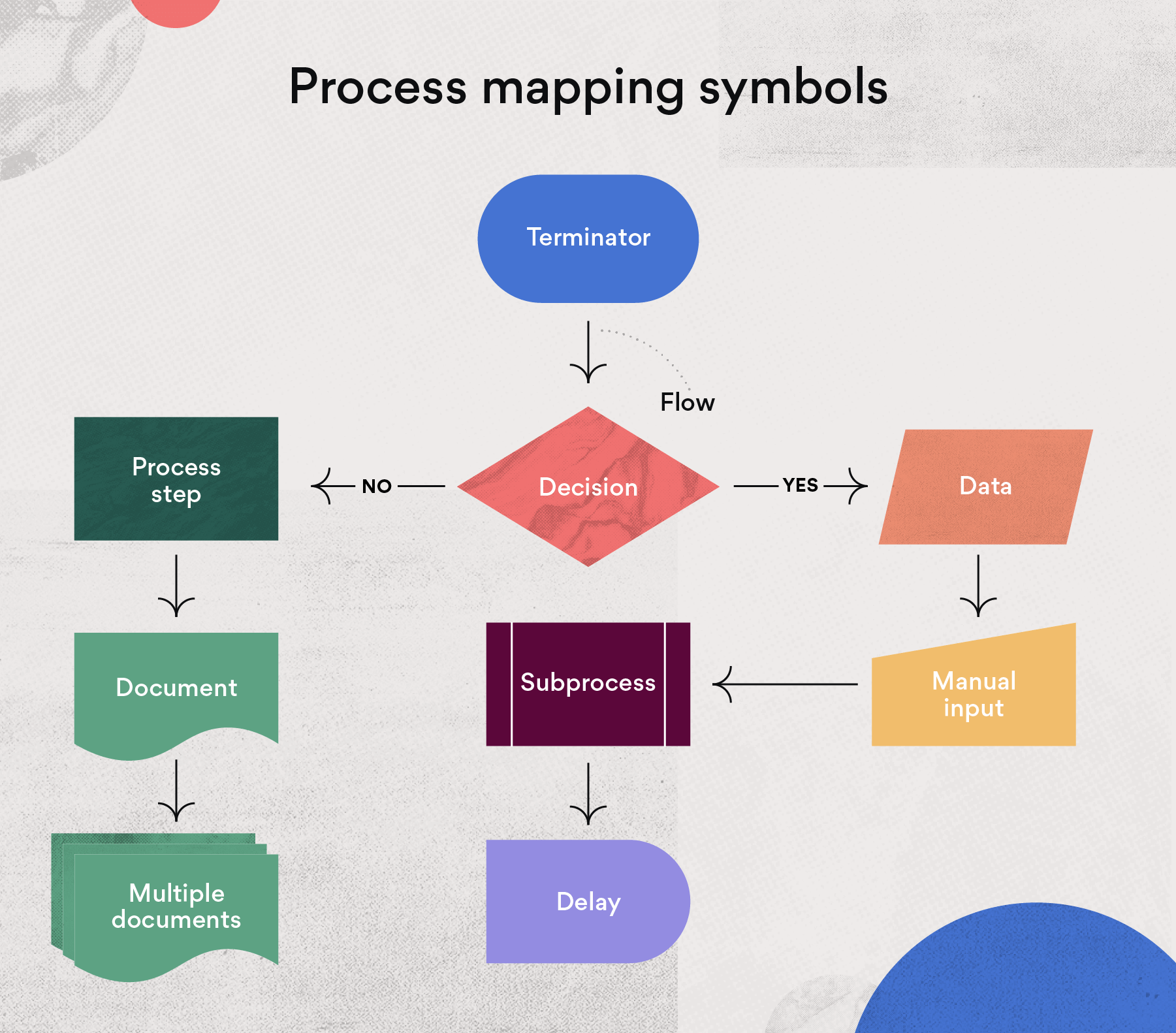

Using the chosen notation, illustrate the process flow from start to finish. Use standard symbols and iconography to depict various process elements.

Step 6: Validate the Map

Review the draft process map with process owners and employees to validate accuracy. Incorporate their feedback to refine the map.

Step 7: Analyze the Map

Analyze the AS-IS process map to identify improvement opportunities, bottlenecks, redundancies, and non-value-adding steps. This analysis provides the basis for the new and improved TO-BE process map.

Tips for Effective AS-IS Process Mapping

Follow these tips to create meaningful AS-IS process maps:

-

Keep it simple – Avoid excessive complexity and only map relevant details. Remember, it is meant to provide an overview.

-

Focus on the process flow – The primary emphasis should be illustrating the process sequence and flow.

-

Be objective – Capture what actually happens, not just what should happen. Base it on facts and observations.

-

Show roles and systems – Call out the roles, systems, and departments involved at each step.

-

Quantify process metrics – Include process performance metrics like cycle times, error rates, and costs.

-

Use standard notation – Follow established flowcharting standards and iconography for uniformity.

-

Iterate the map – Expect to go through multiple iterations of process review to create an accurate map.

AS-IS Mapping Enables Continuous Process Improvement

AS-IS process mapping serves as the crucial first step in an organization’s continuous process improvement journey. It empowers organizations to transition smoothly from current state understanding to enhanced future state processes.

Here is how organizations can leverage AS-IS maps in their improvement programs:

-

Current state assessment – Create AS-IS maps across departments to identify improvement areas and set priorities.

-

Process analysis – Analyze AS-IS maps to pinpoint root causes of inefficiencies like waste, rework, and long cycle times.

-

Future state envisioning – Use insights from AS-IS analysis to create TO-BE process maps outlining a streamlined future state.

-

Change management – Use AS-IS and TO-BE maps to illustrate process changes to stakeholders.

-

Benchmarking – Compare AS-IS maps to identify best practices within or across locations/departments.

-

Training – Incorporate AS-IS maps in training programs to provide process context and overview.

-

Compliance – Leverage AS-IS maps as process documentation evidence for compliance with ISO and other standards.

-

Auditing – AS-IS maps enable auditors to quickly analyze processes and identify control gaps or compliance risks.

Clearly, AS-IS process mapping delivers immense value as organizations pursue process excellence. It serves as the crucial starting point on the journey towards operational efficiency, effectiveness, and business process transformation.

Benefits of analyzing your as-is process

The main advantage of as-is process analysis is creating a solid foundation in an organizationâs processes. As-is analysis allows a business to evaluate the current state of its processes and identify opportunities for improvement.

Without this fundamental information, it is difficult to manage and improve processes. In other words, if you donât know where youâre starting from, youâll have a hard time getting to where you want to be.

By conducting current state and future state process reports, businesses can also expect to:

- Align operations with the business strategy.

- Improve process communication and training.

- Increase operational efficiency.

- Increase control and consistency across the organization.

- Gain a competitive advantage.

Manufacturing flow example (click on to modify online)

Current state vs. future state process analysis

Current state and future state process analysis go hand-in-hand when you are evaluating business processes. Simply put, as-is maps where your processes are and to-be maps where you want them to be.

The as-is phase outlines the current state of your processes and any gaps or issues with the current mode of operation. Once you have that mapped out, you can enter the to-be phase of process management.

To-be process mapping documents what you want the process to look like. Using the as-is diagram, you work with stakeholders to develop improvements to the current process and outline those changes on your to-be map. Lucidchart facilitates collaboration through easy sharing and commenting features. Stakeholders can quickly view your current and future state documents, easily providing feedback through each iteration.

Pro tip: Keeping records of both current and future state documents will help everyone in the organization maintain process consistency and track progress and outcomes more effectively.

Use layers in Lucidchart to document and visualize both the as-is and to-be processes. Hotspots let you toggle between the layers so you can clearly see the differences between the two and easily present your documentation to others.

Process Mapping

How do you create a process map?

The best way to create a process map is to use what look like flow charts. Flow charts specifically made for process mapping allow the users to see the entire process from beginning to end in detail. The visual communication of ideas is what helps speed up the improvement process since every step is broken down into bite sized pieces.

What are the benefits of using a process map?

A process map outlines the individual steps within a process, identifying task owners and detailing expected timelines. They are particularly helpful in communicating processes among stakeholders and revealing areas of improvement. Most process maps start at a macro level and then provide more detail as necessary.

What are the most common symbols used in process maps?

Process maps use visual representations, such as basic symbols to describe each element in the process. Some of the most common symbols are arrows, circles, diamonds, boxes, ovals and rectangles.

What is process mapping?

Process mapping involves creating a visual map of project tasks, including actions to take based on conditional “if/then” outcomes. Learning more about process mapping could help you improve your project efficiency.