Many ecommerce businesses purchase raw materials or finished goods from manufacturers. Ideally, these brands want to purchase just enough inventory to meet demand.

The bad news? Many suppliers institute a minimum order quantity (MOQ). This means that brands must commit to buying a certain amount of stock, because it’s more cost-effective for manufacturers to mass-produce items.

Your brand’s ideal unit count or reorder quantity may not match your manufacturer’s MOQ. However, there are benefits to MOQs – and ways to make them work for you.

In this article, we’ll give an overview of minimum order quantity, take a look at some vital factors to consider when calculating MOQ requirements, and provide tips on how to make the most of MOQs.

If you’ve shopped for wholesale or bulk inventory online, you’ve probably come across the acronym “MOQ” in product listings and policies But what exactly does MOQ stand for and why does it matter when you’re buying or selling products?

In this comprehensive guide, we’ll unravel the meaning of MOQ, why sellers use them, and how minimum order quantities influence pricing and transactions between businesses. Read on to become an MOQ expert!

What Does MOQ Mean?

MOQ stands for “Minimum Order Quantity”. It refers to the smallest number of units a seller requires you to purchase of a particular product in a single order. MOQs are commonly used by manufacturers and wholesalers dealing in bulk volumes.

For example. a listing for wholesale t-shirts may state

“Plain cotton t-shirts, MOQ 100 units.”

This means you’d have to buy at least 100 t-shirts to place an order. Anything less would not be allowed.

Why Do Companies Use MOQs?

There are a few key reasons sellers institute MOQs:

-

To qualify serious business buyers only – screens out small one-off purchases

-

To maintain economies of scale in production – produces items more efficiently in bulk.

-

To justify order processing and shipping costs – overhead per unit decreases as quantity increases.

-

To offer discounted wholesale pricing – incentivizes large volume purchases.

-

To simplify inventory and forecasting – avoids many small orders depleted stock.

-

To match minimum batch sizes – some manufacturing processes require this.

For sellers, fulfilling many tiny orders from individuals can be inefficient and costly. Requiring minimums helps them control expenses and ensures smooth operations.

Common Types of MOQs

While MOQ most often refers to product units or count, you may also encounter minimum quantities based on:

-

Weight – For example, chemicals, raw materials, or foods priced per pound.

-

Volume – Liquids such as industrial solvents measured in gallons or liters.

-

Value – Some sellers require minimum dollar amount totals, like $500.

-

Bundling – Requiring purchases of multiple product variations, like a case pack.

So don’t be thrown off if you see an MOQ referring to something other than simple unit count!

Who Uses MOQs?

MOQs are used across manufacturing, distribution, wholesale, and retail sectors. Here are some examples:

Manufacturers

Factories that produce goods need to optimize production runs. They utilize MOQs to ensure they meet minimum efficient batch sizes. Fulfilling many tiny orders from individuals would be incredibly inefficient.

Distributors

Businesses who acquire large volumes from manufacturers to sell to resellers implement MOQs to focus on their core B2B function. They aim to supply other companies, not individual end consumers.

Wholesalers

Online marketplaces like Alibaba allow wholesalers to connect with small businesses globally. MOQs help them transact efficiently at scale. Small orders don’t justify processing and shipping costs.

Retailers

Some manufacturers also sell direct-to-consumer online. But fulfilling many single-unit orders can be unprofitable. So they set MOQs to prioritize wholesale channels instead.

As you can see, MOQs play an important role across the supply chain in streamlining workflow and minimizing costs.

MOQs vs. Bulk Order Discounts

Note that MOQ is distinct from the practice of offering discounted pricing on large orders, known as volume or bulk discounts.

For example, a seller might set an MOQ of 50 units. But they also offer tiered discounts:

- 10-49 units = $10 per unit

- 50-99 units = $9 per unit

- 100+ units = $8 per unit

The MOQ sets the minimum order size. Bulk discounts incentivize customers to order above that, for additional savings.

How MOQs Influence Pricing

As discussed earlier, MOQs allow sellers to offer better per-unit pricing by optimizing production and amortizing fixed costs over larger order volumes.

Conversely, small orders prevent achieving economies of scale and thus drive up per-unit costs. Sellers use MOQs to avoid this scenario.

For example, a simplified cost breakdown:

- 1,000 units = $1.00 each to produce and fulfill

- 500 units = $1.25 each

- 100 units = $1.75 each

- 10 units = $5.00 each

Requiring say a 250 unit MOQ ensures buyers get better pricing – and sellers maintain profit margins.

Typical MOQ Amounts

What constitutes a reasonable MOQ amount? It varies based on product, industry, and seller. Here are some representative examples:

- Textiles or apparel – often 100+ units

- Fasteners like zippers or snaps – 1000+ units

- Custom printed materials – 250+ units

- Electronics components – 500+ units

- Raw industrial materials – a few pounds or gallons

Keep in mind MOQ levels can change over time as production costs evolve or product demand increases allowing larger production batches.

Negotiating Order Quantities

As a buyer, if an MOQ seems too high, you may be able to negotiate it down depending on factors like your purchase history, order size, or existing relationship with the seller.

For example, a first-time purchase from a new vendor may require accepting their standard MOQ. But after building a buying track record, you may be able to reduce subsequent MOQs through negotiation.

That said, some established manufacturers stand firm on MOQ policies to control costs. So don’t assume there is always flexibility.

Buyer Strategies for Meeting MOQs

What can you do if you want to order from a company but their MOQ exceeds your needs? Here are some options:

-

Request an exception – Ask if they’ll waive the MOQ just once if you’ll promptly reorder at higher volumes.

-

Seek samples first – Order the minimum amount allowed for samples to test quality before committing.

-

Partner to purchase – Team up with other businesses to meet the combined MOQ and split the order.

-

Resell excess inventory – Sell off extra units through other channels like eBay or local stores.

-

Use contract services – For made-to-order items, find contractors to produce only what you need.

-

Switch suppliers – If MOQ is too unreasonable, search for alternate vendors.

With some creativity, smaller buyers can still often find ways to access MOQ restricted inventory.

Key Takeaways

MOQ or Minimum Order Quantity refers to the minimum units or volume a wholesaler or manufacturer requires to fulfill an order. Common reasons for instituting MOQs include:

- Maintaining efficient production batch sizes

- Keeping per unit handling costs low

- Offering the best pricing through bulk discounts

- Streamlining ordering and inventory management

Understanding why MOQs exist allows buyers to appreciate the restrictions sellers face. With some flexibility and negotiation, smaller businesses can still often find ways to purchase from sellers requiring MOQs.

Now that you’re an MOQ expert, you can navigate wholesale and bulk purchasing with confidence! Put your knowledge into practice to unlock the very best pricing.

Incentivize a higher spend on your orders

If you’re getting into wholesale or retail, you can require MOQs for bulk buyers to help ensure retailers pay you a minimum amount. In exchange for a minimum spend, you may choose to offer order volume discounts, where you charge the retailer less per unit in exchange for a higher guaranteed overall spend.

Also, you can adjust the prices to help incentivize higher spend. To do this, you need to set MOQ based on volume or cost. For low-cost items, you need to set a higher MOQ. This ensures you make a profit. For higher-cost items, you can afford to set a lower MOQ. Following this strategy helps you make a profit, no matter if you sell small or large quantities.

Similarly, you can test this strategy for your direct-to-consumer orders by requiring a minimum amount of products to be sold (e.g., 3 bottles of a beverage each priced at $10 to ensure your order value is at least $30) to cover customer acquisition costs and the cost of goods sold.

You can also try this with a free shipping minimum spend threshold, where you require customers to spend a certain amount of money to qualify for free shipping.

Oftentimes, brands will have more SKUs than they should, and they’ll be stuck paying for storage and doling out cash to fulfill MOQs for products that don’t sell or drive revenue.

Keeping your SKU count simple and minimal helps with inventory forecasting. The difference between 20 and 40 SKUs can be hard enough to manage, let alone managing up to 400 SKUs. It’s easy to overestimate the use of new colors and slight variations in products. A lot of the time for ecommerce store experiences, having more than three options is too much to think about.

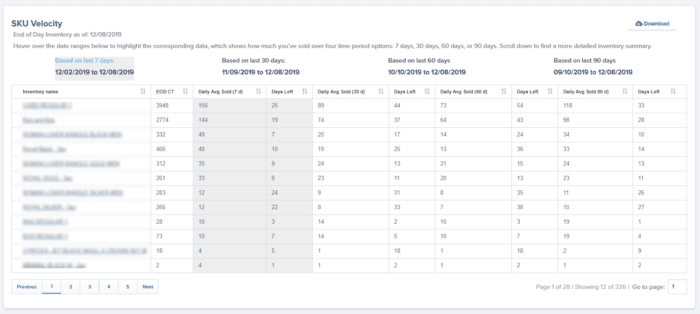

Whether you have a ton of SKUs or just a few, it’s always important to monitor how they’re selling. 3PL partners like ShipBob leverage software that will track your SKU performance for you, so you can always know how quickly SKUs are selling and how much of each SKU you have left.

Ordering excess inventory incentivizes you to have a higher inventory turnover ratio, meaning there’s pressure to sell your inventory quicker because you invested more cash upfront.

If you’re already bound by a supplier MOQ and end up with surplus inventory, seek out creative strategies like running flash sales, bundling extra SKUs with other products, or including them as free gifts in orders. This will help you deplete inventory while still getting some value out of the extra inventory.

If the minimum order quantity is too high and you haven’t proven your business model or product-market fit yet, it’s best to look for a different supplier with a lower MOQ (or none at all). Otherwise, you may end up investing too much money in inventory that may not sell – all while paying higher warehousing costs.

How to calculate minimum order quantity in 4 steps

There is no one right MOQ amount, as many businesses have different requirements. Of course, ecommerce brands and suppliers usually face a tradeoff: they can either set a higher MOQ at a lower price, or pay a higher price per unit for a lower MOQ. While there isn’t a go-to formula for calculating minimum order quantity, you can use the steps below as a starting point.

Before a supplier makes any stock, and before a merchant buys any stock, both parties need to know how much stock they plan on selling. Good demand forecasting takes product type, competition, seasonality, and other factors into account to produce an estimate for how many units a merchant or supplier will sell. This data can help inform your next purchase order.

As an ecommerce merchant, you may find that the supplier’s minimum order quantity isn’t too far off from what you plan to sell through.

For example, say your brand’s demand forecast for the upcoming quarter predicts that you’ll sell 900 stock units. If your supplier has an MOQ of 1,000 units, this difference is manageable. If the product is small (like a bracelet), 100 units may not take much more room to store – and it never hurts to have some safety stock in case demand spikes.

On the other hand, you may find that your supplier’s MOQ is much higher than your expected sales. If your supplier’s MOQ is 1,000 units, but your brand only expects to sell 400 units, you will need to negotiate with your supplier to find a solution.

MOQ – [Minimum Order Quantity] What Does It Mean? (And How To Negotiate It)

What does Moq stand for?

Collaborate with us to bring your vision to life. Contact us now and let’s take your brand to new heights MOQ stands for Minimum Order Quantity, which refers to the smallest number of units you must order from a supplier to fulfill your production request.

What is Moq & how does it work?

The MOQ can be done a per-unit basis, or a dollar figure. Regardless, this MOQ represents at least the minimum for the company to turn a profit on a particular order. There may be set up costs, administrative expenses, minimum amounts of raw materials the supplier can order and other constraints that go into this calculation.

What is EOQ & Moq?

EOQ stands for economic order quantity and it is used to identify the ideal quantity of inventory to keep in stock in your warehouse. This is done so that you don’t spend too much money on storage without running out of products. MOQ is used by sellers or suppliers to identify the minimum purchase amount of a product.

What is a simple Moq?

Many companies that aren’t retailers deal with at least a simple MOQ. This means there is a single restraint on orders. That lower-end limit could be a minimum spend or a minimum quantity ordered. For example, a book printer will likely have a minimum order required.