Simulation engineering is a very complicated and technical field that is very important in many fields, such as aerospace, automotive, manufacturing, and more. You use computer modeling and simulation software as a simulation engineer to make real-life situations look like they would in the workplace and to guess how well systems will work. This helps companies learn important things without having to make and test physical prototypes, which saves them time and money.

To get a job as a simulation engineer, you’ll need to show potential employers your technical skills, problem-solving skills, and communication skills in an interview. For your next interview as a simulation engineer, here are some of the most common questions and how to answer them:

1. Walk me through your experience with computational fluid dynamics (CFD). How have you used it in past projects?

Computational fluid dynamics or CFD is a key simulation technique I have used extensively in my previous roles. The ability to accurately model and predict fluid flow has been invaluable to solving complex problems in aerodynamics heat transfer and combustion engineering.

For example, I used CFD to optimize the design of a turbine blade cooling system for a jet engine. By simulating air flow and heat transfer at different design variations, we were able to improve cooling effectiveness by 15%, enhancing the component’s durability. I have hands-on experience setting up and running CFD simulations using tools like ANSYS Fluent and Star CCM+.

2. Describe a situation where you had to modify or re-develop a simulation model due to changing requirements or new information. How did you approach this challenge?

Changing requirements are common in simulation projects. In one case our team was tasked with modeling a new powertrain design for an electric vehicle. Mid-way through development new battery chemistry data became available, necessitating changes in our model assumptions and parameters.

My approach was to assess the new data and determine the changes needed in the model architecture and governing equations. I worked closely with the cross-functional team to redefine the scope, boundaries, and outputs. We updated the model incrementally and performed regression testing at each stage to ensure changes were valid

Although it required extra effort, the process resulted in a more robust and flexible model that could accommodate future iterations. This experience demonstrated the importance of modular, scalable models as well as agile development practices.

3. How do you determine if a simulation model is accurately representing the real-world system or scenario? What validation techniques do you use?

It is very important to validate simulation models carefully to make sure they give accurate results that you can trust. My approach relies on multiple validation techniques:

-

Comparative testing against physical prototypes or test data across various operating conditions. Models must match real results within an acceptable margin of error.

-

Peer review of model architecture, underlying physics, assumptions, and code implementation.

-

Sensitivity analysis to quantify how uncertainties in inputs affect the outputs. This reveals influential parameters requiring calibration.

-

Statistical methods like hypothesis testing to validate model accuracy within confidence intervals.

-

Partitioning datasets into training and validation subsets prevents overfitting during calibration.

-

Evaluating models under extreme scenarios provides insight into limitations.

Adhering rigorously to these validation practices is key to developing high-fidelity simulations.

4. Explain your experience with real-time simulation. What are some unique challenges with running simulations in real-time?

In my previous role, I worked extensively with hardware-in-the-loop testing which required real-time simulation capability. Some key challenges include:

-

Achieving deterministic execution within tight time constraints to match wall-clock time. This requires optimization of simulation algorithms and efficient code.

-

Handling trade-offs between model fidelity and computational performance. Simplifications may be necessary to execute in real-time.

-

Latency management when simulating large interconnected systems distributed over networks.

-

Synchronizing communication between the simulation and physical components.

-

Rigorous testing across a wide range of conditions to ensure real-time determinism.

To overcome these challenges, I leveraged techniques like parallelization, multi-rate simulation, roll-back mechanisms, and co-simulation. The key is finding the right balance between accuracy and real-time performance.

5. How would you conduct verification and validation for an agent-based simulation model?

For agent-based models, I take a multi-stage approach:

Verification focuses on ensuring proper implementation of agent behaviors and interactions:

- Code reviews and unit testing validate logic and computations.

- Visualization of agent dynamics provides qualitative insight.

- Benchmarking against test models with known outcomes checks correctness.

Validation involves quantitative and qualitative evaluation:

- Varying input parameters over suitable ranges must produce logical outcomes.

- Emergent system behaviors should match real-world counterparts where applicable.

- Sensitivity analysis uncovers influential model factors needing calibration.

- StatisticalTools quantify error and uncertainty in model predictions.

- Collaborating with domain experts adds perspective on conceptual accuracy.

Continuous verification and validation throughout the simulation development life cycle is essential for reliable agent-based models.

6. What are your techniques for optimizing simulation code performance? What tools do you use?

Optimizing simulation code is key to achieving fast, responsive models. My optimization techniques include:

-

Profiling simulations using tools like Valgrind and Gprof to identify performance bottlenecks.

-

Vectorizing code and using parallel processing libraries like OpenMP for multi-core computation.

-

Minimizing function calls and selective use of inline functions to reduce overheads.

-

Caching repetitive computations wherever possible to avoid recalculation.

-

Using just-in-time compilation and iterating on inner loops to boost performance.

-

Converting algorithms to run on GPUs for acceleration in some cases.

-

Simplifying mathematical models when fidelity is not compromised.

-

Utilizing efficient libraries like BLAS, LAPACK for linear algebra routines.

The goal is gaining a 10x or better speedup allowing more simulations within time constraints.

7. How do you manage large data sets generated from simulation models? What techniques do you use to analyze simulation data effectively?

Handling large data is a fact of life in simulation engineering. My approach includes:

-

Storing raw output efficiently on disk or databases, in compressed binary format rather than text.

-

Distributed storage solutions like Hadoop when data size exceeds server capacity.

-

Sampling data spatially and temporally when continuous archival is unfeasible.

-

Visualization via ParaView for interactive querying of multi-dimensional data.

-

Statistical analysis tools like R and Python for insights into data trends.

-

Feature extraction techniques like PCA to reduce dimensionality for ML algorithms.

-

Distributed computing using frameworks like Spark or Dask for big data processing.

The key is having a scalable pipeline from data generation to storage, processing, analysis and visualization while utilizing HPC infrastructure.

8. Tell me about a time you had to debug or troubleshoot a simulation model that was producing inaccurate results. How did you identify and resolve the issue(s)?

Debugging simulations requires structured troubleshooting. Recently, our aerodynamics model was yielding spurious disturbances during a stall simulation.

My first step was sanity checking inputs and assumptions. Next, I added more sensing points to localize the issue. Diving into the code, I found an error in the stall model logic which assumed incorrect flow behavior.

Fixing the implementation improved results significantly. However, some discrepancies remained. I worked with our fluid dynamics expert to refine the stall model itself. We traced the root cause to insufficient mesh resolution near the airfoil.

This example illustrates the importance of methodical and collaborative debugging. The solution often involves code fixes, model improvements and better inputs working together.

9. Describe your experience with design optimization. How have you leveraged simulations to optimize designs in prior roles?

I have used optimization extensively to improve designs by leveraging simulation models. Typical steps include:

-

Defining design variables, constraints, and objective(s) – whether minimizing cost or maximizing performance.

-

Creating a parametric simulation model incorporating the design variables.

-

Automating multiple simulation runs via scripts to evaluate objective(s) across design options.

-

Applying optimization algorithms like genetic algorithms, gradient descent etc. to guide the search.

-

Assessing trade-offs between competing objectives if doing multi-objective optimization.

-

Performing sensitivity analyses to identify drivers of optimal performance.

-

Validating optimized designs against requirements using additional simulations.

This simulation-based optimization approach enabled my team to improve factors like energy efficiency in motor design by over 20% and aircraft wing weight reduction by 15% compared to baseline.

10. How do you determine the appropriate level of model fidelity needed for a simulation? What factors do you consider?

The ideal model fidelity balances accuracy versus complexity. I consider several factors:

-

Simulation objectives – whether it is conceptual evaluation vs final verification.

-

The level of accuracy needed to drive reliable decisions.

-

Available computational resources and time constraints. Complexity affects simulation run times.

-

Availability of high-fidelity data for model development and validation.

-

Cross-functional input from experts on important physics, failure modes etc.

-

The stage within the product development lifecycle. Fidelity requirements evolve over time.

-

Whether a multifidelity modeling approach combining low and high fidelity models is beneficial.

Interviewing as a Process EngineerEmbarking on the journey to secure a role as a Process Engineer involves navigating through a series of interviews that test not only your technical expertise but also your analytical thinking and problem-solving skills. Process Engineers are the backbone of operational efficiency, and their interviews reflect the multifaceted nature of their responsibilities. In this guide, we’ll dissect the array of questions that you, as a Process Engineer candidate, should anticipate. From probing your understanding of process design and optimization to evaluating your ability to manage projects and work collaboratively across departments. We’ll provide you with the tools to craft compelling responses, share insights on the hallmarks of an exceptional candidate, and suggest strategic questions to pose to your potential employers. Our aim is to arm you with the knowledge and confidence required to excel in your interviews and propel your career forward as a Process Engineer.

- Review Core Engineering Principles: Go over basic engineering ideas like thermodynamics, fluid mechanics, and material science again. These are often the basis for technical questions.

- Learn About the Company’s Products and Processes: Find out about the company’s manufacturing methods, the products they make, and the problems they face in their industry. This will let you make your answers fit the situation.

- Learn About Useful Process Engineering Software and Tools: Get to know process simulation software and tools like HYSYS, Aspen Plus, or MATLAB that are commonly used in the field, and be ready to talk about how well you know how to use them.

- To get ready for behavioral questions, think about projects and situations from the past where you used your process engineering skills. Get ready to talk about these events and what you learned from them.

- Learn more about project management and lean principles. Process engineers work on a lot of projects that need good management and lean operations. It can be very helpful to know about project management frameworks and lean methodologies.

- Put together a portfolio of your work. If you can, bring examples of your work, like process diagrams, P

- Prepare Thoughtful Questions: Write down some questions that show you’re interested in the company’s upcoming projects, process problems, and what they expect from you in this role.

- Do mock interviews. Work on your ability to communicate your ideas clearly and professionally by practicing with a friend or mentor. This can also help alleviate interview anxiety.

By following these steps, youll be able to enter the interview with confidence in your abilities and a clear understanding of how you can contribute to the companys objectives. Remember, the goal is not just to answer questions, but to engage in a dialogue that positions you as a valuable asset to the team.

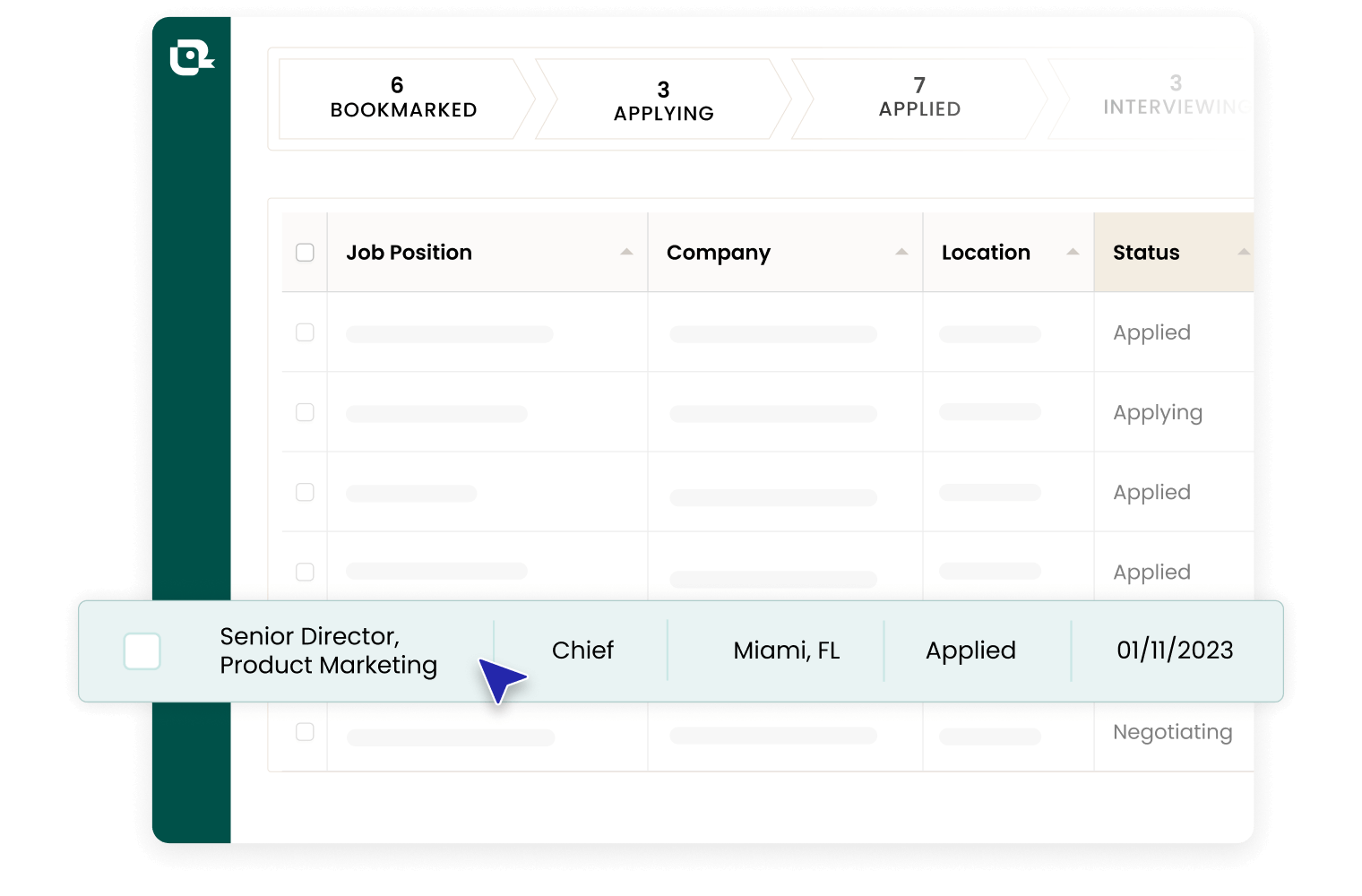

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Interview Simulation

FAQ

What is the role of a simulation engineer?

What qualifications do you need to be a simulation engineer?

What are the 3 questions an engineer has to ask?

What is the role of process simulation engineer?

What are the most common simulation engineer interview questions?

Most interviews will include questions about your personality, qualifications, experience and how well you would fit the job. In this article, we review examples of various simulation engineer interview questions and sample answers to some of the most common questions. Common Simulation Engineer Interview Questions

What questions should I ask during a modeling & simulation interview?

Here are 20 commonly asked Modeling and Simulation interview questions and answers to prepare you for your interview: 1. What is a system model? A system model is a simplified representation of a system that is used to aid in understanding the system.

Why should you ask a simulation engineer a job interview?

This question is a great way for hiring managers to gauge your practical experience and problem-solving skills. A simulation engineer’s role often involves dealing with complex projects, requiring not only technical knowledge but also a strategic approach to project management.

What are interviewers looking for from a simulation specialist?

Learn what skills and qualities interviewers are looking for from a simulation specialist, what questions you can expect, and how you should go about answering them. Simulation specialists create models that help organizations understand complex systems and make better decisions.