Although it may seem tedious, estimating a construction project is crucial to the success of your construction company.

If you don’t estimate how much a job will cost before you complete it, you could end up shortchanging yourself or becoming overwhelmed by a project you can’t currently handle.

The thought of creating a construction estimate may be intimidating if you don’t have much experience with it. But it doesn’t have to be.

In this article, we’ll detail the 7 steps you can take to create an accurate estimate that maximizes your profit.

Accurately estimating construction projects is a crucial skill for contractors and construction companies. Proper estimates account for all costs and prevent unexpected losses down the line. This guide covers key steps, best practices, and tips for learning how to estimate construction jobs like a pro.

Overview of Construction Estimating

Estimating is the process of predicting the total costs and requirements of a construction project before work begins. Estimates allow contractors to bid competitively and set accurate project budgets. The estimate accounts for:

- Material, equipment, and labor expenses

- Overhead like insurance, bonds, permits, andIndirect costs

- Desired profit margin

- Contingencies for unforeseen expenses

Thorough estimates require gathering extensive project details, from engineering plans to site conditions. Estimators combine this data with costs researched from material suppliers, vendors, and subcontractors. Estimating is both an art and science—it improves through training and experience.

8 Steps to Estimate Construction Projects

Follow these key steps when learning how to estimate any construction job:

1. Review the Bid Package

The bid package or tender documents provide the scope of work. Study blueprints, project specifications, quantity takeoffs, and other details. Identify required materials, project phases, construction methods, and standards.

2. Visit the Job Site

A site visit allows you to visualize the project and spot aspects that may impact costs. Note the terrain, access points, space constraints, nearby buildings, and other site conditions. Take photos and measurements as needed.

3. Perform a Quantity Takeoff

Take off quantities from the drawings for all materials required. This includes concrete, lumber, drywall, rebar, fixtures, and more. The takeoff allows you to get accurate material pricing.

4. Request Supplier and Subcontractor Quotes

Contact vendors to get price quotes on materials for the project Reach out to subcontractors like electricians and plumbers to get estimates for their trade work

5. Evaluate Labor Requirements

Determine the workers needed and estimate hours for each task. Consider specialized skills required and prevailing wage rates. Include your own crews and additional hired labor.

6. Calculate Overhead Costs

Factor in overhead like insurance, bonds permits equipment, site office, temporary utilities, and supervision costs. Determine overhead as a percentage of direct costs.

7. Account for Profit

Decide the profit as a percentage of the total estimate, such as 10-20%. This compensates you for risk and effort.

8. Add Contingencies

Pad estimates by 5-10% to cover unexpected expenses. This contingency allowance prevents losing money if costs run over.

Best Practices for Accurate Estimating

Follow these tips and strategies to hone your estimating approach:

-

Use estimating software like Sage for efficient takeoffs and data organization.

-

Create a standardized estimating template to easily compile and compare estimates.

-

Build a historical cost database to reference for future estimates.

-

Get several bids from subcontractors and average for your estimate.

-

Pad uncertain items with higher contingencies.

-

Include escalation costs for projects spanning over one year.

-

Overestimate rather than underestimate costs.

-

Clearly list exclusions and assumptions in your estimate.

-

Perform multiple independent estimates and reconcile major differences.

-

Update estimates when the scope of work changes.

-

Clearly communicate estimate details to your team.

Common Estimating Mistakes to Avoid

Don’t derail your estimating accuracy by making these common mistakes:

- Not fully understanding the project requirements and specifications

- Using outdated pricing information from vendors and suppliers

- Forgetting small costs like fasteners, consumables, and waste disposal

- Underestimating labor productivity and work durations

- Failing to get subcontractor bids in writing

- Not accounting for site conditions like access and logistics

- Skipping steps in quantity takeoffs

- Relying too much on software instead of hands-on checking

- Using insufficient or zero contingencies

- Not estimating overhead costs accurately

- Copying estimates without making project-specific adjustments

Improving Estimating Skills with Experience

Estimating requires combining hands-on field experience with analytical skills. Here are tips for builders at all levels to improve estimating:

Entry-level: Learn takeoff methods, study blueprints, master estimating software, and review historical costs.

Mid-level: Visit job sites, interact with crew foremen, compare takeoffs with seniors, and reconcile estimate variances.

Senior-level: Track actual costs during projects, create estimating templates, coach junior estimators, and refine your approach.

All levels: Participate in bids, keep current on costs, attend industry events, learn from competitors, and stay up-to-date on regulations.

Estimating is a complex but essential skill for the construction industry. Following structured processes, leveraging technology, tapping field knowledge, and continually improving will help perfect your estimating game. Tight estimates require diligence, experience, and attention to detail.

With careful pre-project estimating, contractors avoid cost overruns and delays down the line. Dialed-in estimates lead to maximized profits and competitive bidding advantages. Use this guide to implement proven estimating strategies and principles in your construction business. Soon you’ll be estimating construction projects accurately and efficiently like the pros.

Step 3: Estimate Construction Material Costs

Because they’re usually the most straightforward expenses, we recommend starting your construction estimate by calculating your material costs.

Construction materials include things like wood for framing, flooring, brick or stone for building, and so on.

You can shop around to get a good idea of the cost of the materials in the quantity you’ll need. Or, if you have established relationships with suppliers, ask them for quotes.

Before you seek material quotes, make sure you know

- How the material is sold (e.g., cubic feet, sheets, bundles)

- How much square footage each unit covers

- Price per unit

- Project site square footage

Estimating Software for Construction

Step 1: Do Your Construction Job Pre-Check

It’s impossible to accurately estimate a construction project if you don’t know the scope of the job. That’s why your estimating process should always start with a pre-check of the site to get an idea of what’s required.

How to Estimate Construction Projects Quickly

How do I make a construction estimate?

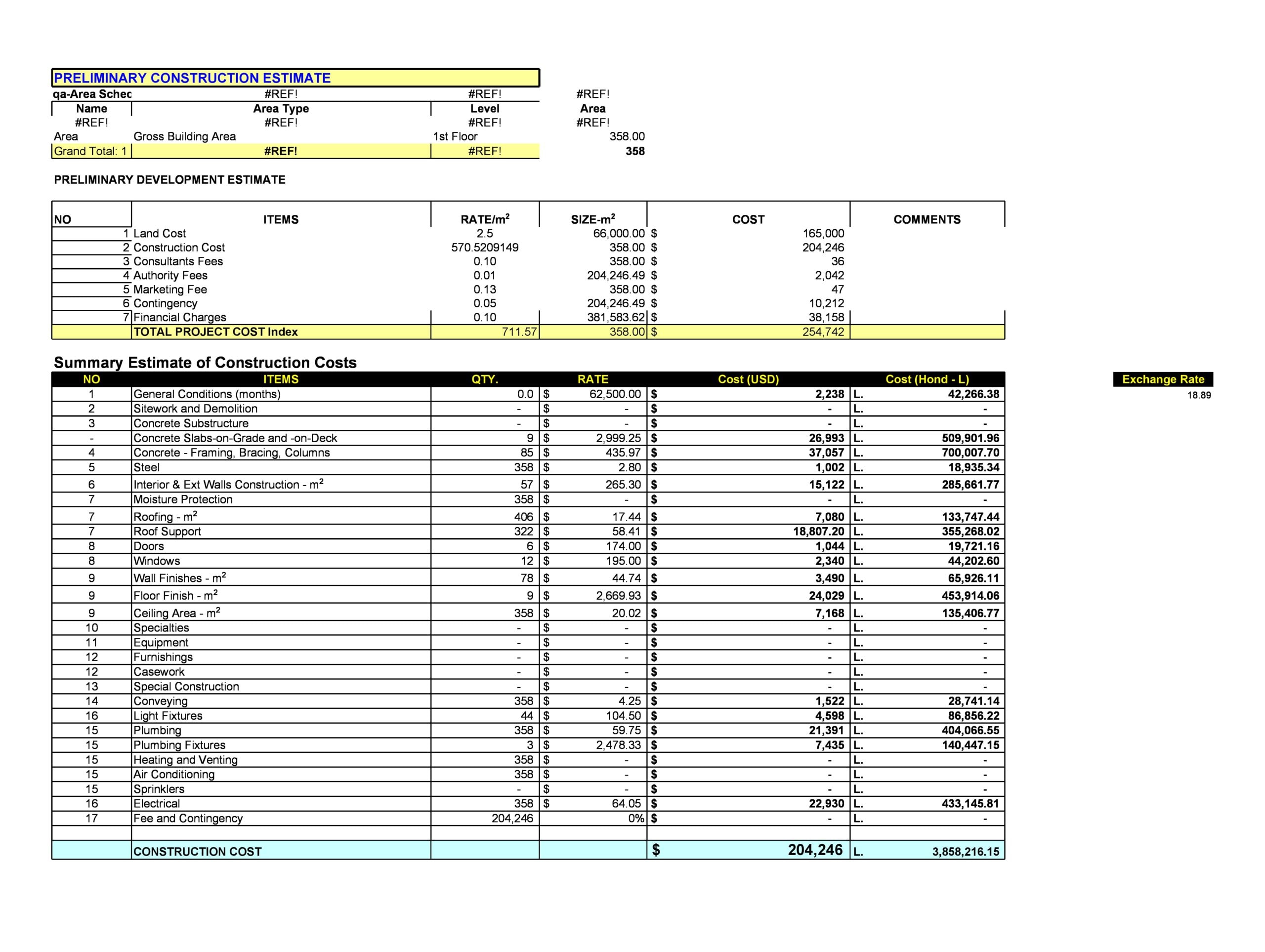

Estimate Costs & Create a Construction Estimate Once you write a scope of work, a material takeoff and a bill of quantities, you should have a clear idea of what labor, materials, equipment and machinery are needed for your construction project, which means you can now clearly estimate their costs and make a construction estimate.

Is construction estimating easy?

Like many things, construction estimating is only difficult if you’re underprepared. However, by using online estimating software and other advanced tools like FreshBooks, you’ll find that generating accurate construction estimates is actually quite straightforward. How do you estimate construction costs for a project?

When is a construction estimate done?

You might amend some costs, or find that scheduling or other delays will add to the budget, but the construction estimate process is done once all the documentation for your project is complete and you have a full view of what everything should cost. Use this free Construction Estimate Template for Excel to manage your projects better.

How much does a construction job cost?

So, if your hourly labor cost is $20 and the job requires 560 total labor hours, your total labor costs would be $11,200. If you’re going to need to subcontract out any work for the project, don’t forget to include those costs in your estimate too. Construction jobs often require the use of a lot of expensive tools and machinery.