To calculate manufacturing overhead, you need to add all the indirect factory-related expenses incurred in manufacturing a product. This includes the costs of indirect materials, indirect labor, machine repairs, depreciation, factory supplies, insurance, electricity and more.

Manufacturing overhead is also known as factory overheads or manufacturing support costs. Overhead costs such as general administrative expenses and marketing costs are not included in manufacturing overhead costs.

Manufacturing overhead costs are all the indirect expenses incurred during the manufacturing process These costs are not directly tied to producing products but are still vital for manufacturing operations, Properly tracking and allocating overhead costs is crucial for businesses to understand their true profit margins,

This article will provide a step-by-step guide on how to calculate manufacturing overhead. We will cover key definitions, overhead cost examples, methods of allocation, and tips for accurate overhead costing. Whether you are a small shop or a large factory, these principles will help you gain control of this major expense category.

What is Manufacturing Overhead?

Manufacturing overhead refers to all indirect production costs that cannot be directly traced to manufacturing a specific product. These expenses are also known as “factory burden” or “factory overhead.”

Manufacturing overhead includes:

-

Indirect labor costs – wages of plant supervisors, material handlers, maintenance workers etc

-

Indirect material costs – consumables, plant supplies, spare parts, lubricants etc.

-

Utilities – electricity, water heating etc. for production facilities

-

Equipment costs – depreciation, rent, repairs, insurance

-

Building costs – depreciation, rent, property taxes, insurance

-

Quality control and inspection

Basically, overhead includes any manufacturing cost that is not direct material or direct labor. While overhead costs do not go into the final product, they are necessary for production activities.

Why Calculate Manufacturing Overhead?

There are two main reasons manufacturers need to calculate overhead costs:

1. Absorb Overhead into Product Costs

Manufacturing overhead needs to be properly allocated to individual units produced. This allows the full cost of production to be captured in the inventory valuation.

Only direct material and direct labor can be traced directly to products. Overhead costs have to be spread across production in a systematic way.

2. Control Overhead Costs

Manufacturing overhead is usually the largest component of product cost. Monitoring overhead costs is vital for controlling production costs.

By allocating overhead to cost centers, management can identify which departments are incurring the most significant overhead costs. This allows targeted actions to improve efficiency and reduce overhead expenses.

Accurately calculating overhead also helps identify the true net profit margin earned on products. Management can use this for data-driven decision making.

How to Calculate Manufacturing Overhead Costs

Here are the key steps involved in overhead costing:

1. Identify Overhead Costs

First, list all manufacturing overhead expenses for the accounting period under consideration. Typical overhead costs include:

- Factory rent and utilities

- Equipment leases, depreciation

- Indirect labor – supervisors, inspectors

- Indirect materials – lubricants, cleaning supplies

- Insurance, property taxes

- Factory administrative salaries

- Amortized cost of software licenses, ERP systems

- Repairs and maintenance

- Safety and security expenses

- Other variable or fixed overhead items

Review prior periods’ financial statements to compile a comprehensive overhead listing.

2. Divide into Cost Centers

Next, assign overhead costs to logical cost centers. Cost centers segment overhead expenses by department or process.

Common cost centers in manufacturing include:

- Material handling department

- Machining department

- Assembly department

- Packaging area

- Quality control area

- Plant management

Assign each overhead item to the cost center that benefits from or drives that cost. This allows overhead to be pooled by cost center.

3. Allocate Overhead to Cost Centers

Some overhead costs apply to multiple cost centers. In that case, an allocation method is needed to divide the cost.

For example, the factory’s rent could be allocated across departments based on square footage occupied. Shared equipment costs could be allocated based on usage hours.

Determine an appropriate driver to distribute each shared overhead cost across centers. This fully allocates overhead so each center is charged with its portion of company-wide overhead.

4. Calculate Overhead Rates

Within each cost center, sum the overhead costs to determine the total overhead pool. Then divide this pool by the allocation base to determine the overhead rate:

- Overhead Rate = Total Overhead Costs / Allocation Base

The allocation base represents the activity driving overhead costs. Common allocation bases include:

- Direct labor hours

- Machine hours

- Units produced

- Direct labor cost

The goal is to choose a base that causes overhead to fluctuate proportionately. Use the base already tracked for production activities.

5. Assign Overhead to Products

When goods are manufactured, apply the overhead rate to assign overhead costs to individual units.

For example, using direct labor hours as the allocation base:

- If the overhead rate is $20 per direct labor hour

- And a batch required 500 direct labor hours

- The overhead assigned to the batch is $20 * 500 hours = $10,000

Do this allocation for each product to absorb its portion of manufacturing overhead costs.

6. Compare to Actual Overhead

At the end of the period, compare allocated overhead to actual overhead incurred. If actual costs were higher, the difference is underapplied overhead. If actual costs were lower, it is overapplied overhead.

Under or overapplied overhead is typically small and carried forward to adjust next period’s overhead rate. But large discrepancies may indicate a problem with the allocation method.

Example of Overhead Cost Calculation

Let’s look at an example overhead calculation for a furniture manufacturer:

Overhead Costs

- Factory rent: $100,000

- Electricity: $8,000

- Indirect labor: $12,000

- Depreciation on Plant Equipment: $20,000

Total overhead costs = $140,000

Cost Centers

- Cutting Department

- Assembly Department

- Finishing Department

Allocation Base

- Direct labor hours

Cutting used 2,000 direct labor hours

Assembly used 1,500 direct labor hours

Finishing used 500 direct labor hours

Total direct labor hours = 4,000

Overhead Rates

Cutting = $140,000 / 4,000 hours = $35 per direct labor hour

Assembly = $35 per direct labor hour

Finishing = $35 per direct labor hour

Product Overhead

Batch A used 100 direct labor hours in Cutting. Its overhead is 100 * $35 = $3,500

Simple overhead calculations like this example can be extended to handle even complex manufacturing environments. The key is a systematic methodology for identifying, allocating, and absorbing overhead costs.

Tips for Managing Manufacturing Overhead

Here are some tips for gaining better control over overhead costs:

- Update overhead costs regularly as expenses change

- Break down general overhead accounts to improve visibility

- Use allocation bases that cause overhead to fluctuate with activity

- Calculate department-level overhead rates to pinpoint high overhead areas

- Identify steps to reduce variable overhead costs

- Question expenditures that don’t directly support production

- Invest in automation and technology to reduce labor-related overhead

- Benchmark overhead performance against other manufacturers

Major Benefits of Overhead Costing

Calculating manufacturing overhead provides major benefits:

- Values inventory more accurately for financial reporting

- Absorbs full production costs into product costs for better pricing decisions

- Highlights overhead cost drivers for expense reduction opportunities

- Allows activity-based costing by tracing overhead to products

- Determines true net profitability by product, customer, or project

While overhead costing takes effort, the visibility it provides into production costs is invaluable. Companies that neglect overhead run the risk of losing money on products that appear profitable from direct costs alone.

Manufacturing overhead represents a significant cost for producers. Proper overhead accounting and allocation provides critical insights into production economics.

This guide covered overhead cost calculations from start to finish. Key steps include identifying overhead, assigning to cost centers, determining allocation rates, and absorbing into production. Compare allocated overhead to actual regularly.

With a sound overhead costing process, manufacturers gain vital visibility into profit margins and opportunities to streamline operations. Overhead cost analysis should be a priority for producers looking to optimize their financial performance.

What Is Included in Manufacturing Overhead?

You need more than labor and raw materials to manufacture products. Manufacturing units need factory supplies, electricity and power to sustain their operations.

Examples of manufacturing overhead costs are:

- Rent of the production building

- Property taxes and insurance on manufacturing facilities and equipment

- Communication systems and computers for a manufacturing facility

- Depreciation on manufacturing equipment

- Salaries of maintenance personnel

- Salaries of factory management team

- Salaries of the material handlers

- Salaries of the quality control staff

- Factory supplies not directly associated with products

- Utilities for factory

- Janitorial staff wages

All the items in the list above are related to the manufacturing function of the business. These costs exclude variable costs required to manufacture products, such as direct materials and direct labor.

How Do You Calculate Allocated Manufacturing Overhead?

In order for a manufacturer’s financial statements to be in compliance with GAAP, a portion of the manufacturing overhead must be allocated to each item produced.

To allocate manufacturing overhead costs, an overhead rate is calculated and applied. When this is done in a precise and logical manner, it will give the manufacturer the true cost of manufacturing each item.

- Calculate the total manufacturing overhead costs. While some of these costs are fixed such as the rent of the factory, others may vary with an increase or decrease in production.

- Select an allocation base. The allocation base is the basis on which a business assigns overhead costs to products. The commonly used allocation bases in manufacturing are direct machine hours and direct labor hours.

- Divide the manufacturing overhead costs by the allocation base to calculate the amount of manufacturing overhead that should be assigned to each unit of production.

- Determine the total of the allocation base generated in the current period by reviewing the maintenance and payroll records of the factory. The payroll records, for example, will show 2,000 direct labor hours during the current period.

- Divide the allocation base value by the number of units produced. This provides the amount of manufacturing overhead attached to each unit of the allocation base.

For instance, if a factory has $2,000 in overhead costs and 500 direct labor hours, there is an overhead of $4 ($2,000 / 500) attached to each labor hour.

The allocation of costs is necessary to establish realistic figures for the cost of each unit manufactured.

Manufacturing overhead is an essential part of running a manufacturing unit. Tracking these costs and sticking to a proper budget can help you to determine just how efficiently your business is performing and help you reduce overhead costs in the future.

Manufacturing Overhead

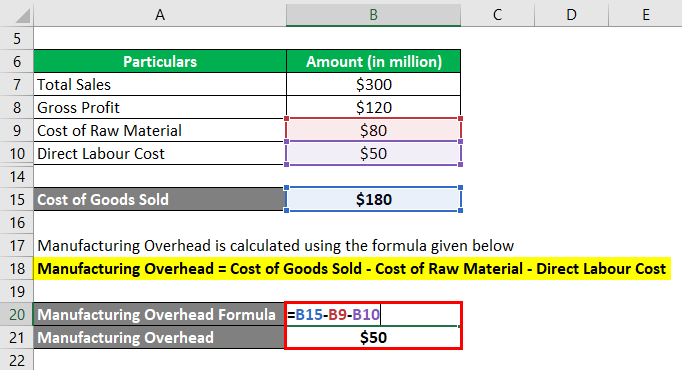

How do you calculate manufacturing overhead?

Manufacturing overhead = Indirect materials + Indirect labor + Utilities + Physical costs + Financial costs + Additional manufacturing expenses After adding together all of the indirect expenses necessary to produce your product, this formula will give you the total dollar amount of manufacturing overhead. 3. Determine the cost per unit

What is manufacturing overhead cost?

Manufacturing overhead (MOH) cost is the sum of all the indirect costs which are incurred while manufacturing a product. It is added to the cost of the final product along with the direct material and direct labor costs.

How to allocate manufacturing overhead costs?

To allocate manufacturing overhead costs, an overhead rate is calculated and applied. When this is done in a precise and logical manner, it will give the manufacturer the true cost of manufacturing each item. Calculate the total manufacturing overhead costs.

What is an example of manufacturing overhead?

Let’s now look at an example of manufacturing overhead. Consider Tillery Manufacturing, a business that makes shoes. In a good month, Tillery produces 100 shoes with indirect costs for each shoe at $10 apiece. The manufacturing overhead cost would be 100 multiplied by 10, which equals 1,000 or $1,000.