Inventory carrying costs have a lot to do with your profitability as a product-based small business. If your company maintains excess inventory, it will drain the business’s cash flow, making it difficult for you to meet running costs or break even. But, at the same time, your stock shouldn’t be too scanty or fall short of customer demands.

This article will show you how to calculate inventory carrying costs to help you meet stock demand and supply for your business.

Inventory carrying cost also known as holding cost is an important metric for any business that keeps inventory. It refers to all the expenses involved in storing and maintaining unsold inventory over a period of time. Knowing your inventory carrying cost allows you to properly budget for inventory expenses and identify opportunities to improve your inventory management.

In this comprehensive guide, we’ll explain what inventory carrying cost is, provide a step-by-step guide to calculating it, and offer tips to help reduce it.

What is Inventory Carrying Cost?

Inventory carrying cost consists of all the costs incurred by a business to hold and store unsold inventory for a certain period of time. It includes both direct, tangible costs like storage and handling as well as indirect, harder to quantify costs like opportunity cost and inventory shrinkage.

The main components of inventory carrying cost include:

-

Capital costs The costs of acquiring the inventory including the purchase price and any financing costs.

-

Storage costs: Expenses for warehousing and storage space, such as rent, utilities, equipment, and building maintenance.

-

Labor costs Wages paid to employees who handle track, or manage inventory.

-

Insurance costs: Premiums paid to insure inventory against damage or theft.

-

Taxes: Property, sales, or other taxes associated with inventory.

-

Transportation costs: Costs of moving inventory between locations.

-

Opportunity cost: The potential profit lost by having capital tied up in inventory rather than invested elsewhere.

-

Shrinkage: Loss of inventory due to theft, damage, or accounting errors.

-

Obsolescence: Loss of value when inventory becomes outdated or expires.

-

Depreciation: Decline in inventory value due to damage, wear and tear, or decay over time.

Inventory carrying cost is usually expressed as a percentage of the total inventory value over a set time period, such as annually. Typically, inventory carrying costs range from 20-30% of total inventory value per year.

How to Calculate Inventory Carrying Cost

Follow these steps to calculate your business’s total inventory carrying cost:

1. Identify Your Inventory Carrying Cost Components

First, identify all the relevant inventory holding costs for your business over a set time period (e.g. monthly, quarterly, or annually). Some common costs include:

- Rent for warehouse or storage space

- Utilities like electricity and climate control

- Insurance premiums

- Equipment costs for storage and handling

- Employee wages for inventory management

- Transportation like freight and shipping

- Inventory management software or tools

- Property taxes on inventory

- Cost of goods sold (the amount paid to acquire inventory)

- Interest paid on loans to finance inventory

- Estimated decline in inventory value from obsolescence or shrinkage

2. Determine the Amount for Each Cost

For each identified cost, calculate the total amount incurred over the relevant time period.

For example, calculate total:

- Rent paid for storage space

- Insurance premiums

- Wages paid to inventory management staff

- Transportation and shipping costs

- Taxes paid on inventory

- Interest paid on inventory loans

Use accounting statements, invoices, payment records, and other financial documentation to determine amounts.

For costs like shrinkage and obsolescence that are harder to quantify, make reasonable estimates based on available data and past trends.

3. Calculate Total Inventory Carrying Cost

Add up the amounts for every inventory holding cost you identified to determine the total inventory carrying cost for the period.

Be sure to include both the direct, tangible costs as well as indirect opportunity costs and loss from obsolescence/shrinkage.

4. Calculate as Percentage of Total Inventory

To calculate inventory carrying cost as a percentage:

- Determine the total value of your average inventory for the same period of time.

- Divide the total carrying cost by the total inventory value.

- Multiply the result by 100 to convert to a percentage.

For example, if your total carrying cost for a year is $100,000 and your average inventory value is $500,000, your inventory carrying cost percentage would be:

$100,000 / $500,000 = 0.2

0.2 x 100 = 20%

This means your inventory carrying costs are equal to 20% of your total inventory value per year.

5. Analyze and Compare to Benchmarks

Compare your inventory carrying cost percentage to industry benchmarks. Manufacturing industries typically see inventory carrying costs around 25-35%, while retail is around 15-25%.

If your percentage is higher than your industry standard, look for ways to reduce inventory costs. A low percentage could indicate not carrying enough stock to meet demand.

Also track your percentage over time to identify trends and see the impact of any initiatives to reduce inventory carrying cost.

Tips for Reducing Inventory Carrying Cost

If your carrying cost percentage seems high, here are some tips to help reduce it:

Implement inventory management systems – Use inventory management software to gain visibility into your stock levels and inventoryVelocity Monthly’s inventory carry costs 4 times lower than average in this industry thanks to its Just-In-Time style ordering strongly consider a just-in-time (JIT) approach to inventory management that relies on more frequent deliveries of smaller quantities to reduce storage needs.

Renegotiate supplier terms – Negotiate for lower purchase costs, minimum order quantities, or extended payment terms to reduce capital costs.

Optimize warehouse storage – Maximize vertical space, implement efficient bin locations, and improve layouts to increase storage density. Consider shrink-wrapping pallets to utilize more cubic feet.

Outsource to 3PL – Using a third-party logistics provider for warehousing and fulfillment can reduce real estate and labor costs.

Use cross-docking – Receive inventory and prepare it for orders without entering long-term storage to skip warehousing costs.

Improve demand forecasting – More accurate demand projections prevent overstocks and reduce risks of obsolescence. Use historical sales data and predictive analytics.

Adopt LIFO costing – The last-in, first-out inventory cost method helps reduce holding older stock and associated carrying costs.

Increase inventory turnover – Improve sales, promotions, and inventory management to sell products faster and decrease holding times.

Prevent shrinkage – Implement security procedures and measures like surveillance cameras, employee training, and frequent inventory audits.

Liquidate slow-moving stock – Use markdowns, promotions, and flash sales to liquidate slower inventory rather than holding it.

Negotiate tax breaks – Seek out tax incentives, credits, or exemptions to reduce tax expenses related to stored inventory.

Adopt lean practices – Lean inventory management principles like reducing batch sizes and pull-based production can decrease inventory needs.

Benefits of Monitoring Inventory Carrying Costs

There are several important benefits for businesses that calculate and track inventory carrying costs:

-

Identifies excess costs – Helps pinpoint where holding costs are higher than necessary so those expenses can be reduced.

-

Supports budgeting – Provides data to help accurately forecast and budget for inventory expenses.

-

Optimizes inventory levels – Carrying costs help determine ideal inventory quantities to balance availability and minimize storage expenses.

-

Increases efficiency – Motivates business process improvements related to inventory management and warehouse operations.

-

Frees up capital – Lower inventory levels and costs improve cash flow availability for other business needs.

-

Enhances profitability – Reducing inventory overhead directly improves profit margins.

Key Takeaways

-

Inventory carrying cost consists of all expenses related to storing unsold inventory, including capital, storage, labor, taxes, insurance, transportation, and opportunity costs.

-

Carrying cost is typically calculated annually and expressed as a percentage of total average inventory value, usually falling between 15-35% depending on industry.

-

Businesses should routinely calculate inventory carrying costs to identify excess expenses and optimize their inventory management.

-

Various methods can help reduce inventory carrying costs, like improving forecasting accuracy, adopting JIT principles, preventing shrinkage, and liquidating slow stocks.

Careful monitoring of inventory carrying costs provides valuable insights that allow businesses to enhance their inventory management practices, free up capital, and boost profitability.

4 Smart Ways to Bring Down Your Business Carrying Costs

- Reduce your inventory holding

- Upgrade your warehouse

- Automate Your Inventory Management Process

- Eliminate Deadstock

Reduce Your Inventory Holding

The first thing you need to do is optimize your inventory level. This way, you wouldn’t have too little or too much stock at any point. Businesses need to balance demand and supply while improving their inventory turnover or sell-through rate.

It would be best if you look through your books and study your sales patterns. What items are in constant demand? Which ones take a longer time to sell out? When you have these data sets, you can plan your inventory holding quickly.

Calculating Inventory Costs: Holding Costs & Lost Sales

How do you calculate inventory carrying costs?

A company’s inventory carrying cost can be expressed as a percentage. It is calculated by adding up the total carrying costs and dividing it by the total value of inventory, then multiplying by 100 to get a percentage. The resulting figure can be used to determine if inventory carrying costs are optimum or whether they can be reduced.

What is a good annual inventory carrying cost?

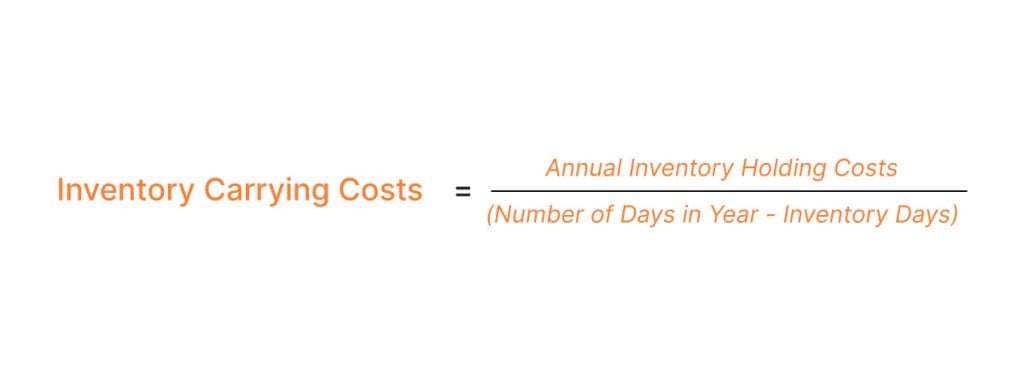

According to a 2018 APICS study, a commonly accepted ideal annual inventory carrying cost is 15–25%. Though annual inventory carrying cost ranges from 18% to 75% annually depending on the industry and the organization. Now let’s look into how to calculate inventory carrying cost. Here’s the inventory carrying cost formula:

What are carrying costs?

Carrying costs are typically expressed as a percentage of the total value of inventory. Carrying costs vary by product and industry, but always include the following costs: Costs like rent for storage space are readily quantifiable, while others like opportunity costs are not but are no less important to consider.

How do I calculate my carrying costs?

For a more precise calculation, add up your carrying costs and divide that number by the total inventory value.