A crucial factor in demand planning is forecast accuracy or reliability. It will enable you to decrease stock-outs, boost service levels, and lower the cost of your supply chain if properly chosen and measured. Learn in 5 steps how to implement the appropriate KPI in your business and master forecast accuracy formulas.

There are numerous ways to evaluate the accuracy of sales forecasts. I read a lot of reference materials, talked to experts, and compared them to my own sales forecasting experiences as part of my extensive study of them. I came to the conclusion that there is no ONE perfect method and that the numerous solutions that do exist are like a maze of mathematical formulas. Sorting through them can be difficult.

The best course of action for you to take is to pick a consistent method that is simple to implement and maintain and that enables you to quickly assess the accuracy of your sales forecasts.

I’ll go through the entire process with you step-by-step, from choosing the parameters to the specifics of the calculation.

- BIAS = Historical Forecast Units (Two-months frozen) minus Actual Demand Units.

- If the forecast is greater than actual demand than the bias is positive (indicates over-forecast). …

- On an aggregate level, per group or category, the +/- are netted out revealing the overall bias.

Forecast Bias

Introduction: What is a Good Level of Forecast Accuracy?

What would you consider a good level of forecast accuracy in our business? is the one inquiry we receive most frequently from clients, consultants, and other business experts.

However, we feel that isn’t the right question to ask. First off, forecasting is never the end in any context of supply chain or retail planning; it is always a means to an end. Remember that a forecast is only useful if it helps us achieve other objectives, like increased shelf availability, decreased food waste, or more efficient assortments.

Secondly, although forecasting is an important part of any planning activity, it still represents only one cogwheel in the planning machinery, meaning that there are other factors that may have a significant impact on the outcome. Oftentimes the importance of an accurate forecasting is truly crucial, but from time to time other factors are more important to attaining the desired results. (You can read more about how this can be seen in a store replenishment context in a recent master’s thesis commissioned by RELEX.)

Of course, we’re not advocating that you stop evaluating forecast accuracy altogether. It is a crucial tool for root cause analysis and for quickly spotting recurring changes in forecast accuracy. However, in order to truly benefit from measuring forecast accuracy, you must comprehend:

1. The role of demand forecasting in attaining business results. When managing products with a limited shelf life, such as fresh foods, forecast accuracy is essential. However, other aspects of your planning procedure may have a greater impact on your business outcomes for other products, such as those that are slow-movers and have a long shelf-life. Do you know which goods and circumstances forecast accuracy is a major factor in determining business outcomes?

2. Demand forecasts are inherently uncertain, which is why we refer to them as forecasts rather than plans. What factors affect the achievable forecast accuracy? But demand forecasting is simpler in some situations than in others. Do you know when you should rely less on forecasting and when, on the other hand, your operations should be set up to be more forgiving of forecast errors?

3. How to assess forecast quality. Although forecast metrics can be used to track performance and spot anomalies, how can you determine whether your forecasts are already of a high caliber or whether there is still a sizable amount of room for improvement?

4. How the main forecast accuracy metrics work. Depending on the chosen metric and how the calculations are done, the same data set can yield excellent or terrible results when measuring forecast accuracy. Do you understand why?.

5. How to monitor forecast accuracy. No forecast metric is universally better than another. Do you understand how to use the forecast accuracy formula?

We will discuss these aspects of forecasting and why forecast accuracy makes a good servant but a bad master in the chapters that follow.

Chapter 1: The Role of Demand Forecasting in Attaining Business Results

The value of a forecast comes from using it as part of a planning process if you are not in the business of making weather predictions.

Good demand forecasts reduce uncertainty. The advantages of accurate forecasting in retail distribution and store replenishment include the ability to achieve excellent product availability with reduced safety stocks, minimized waste, and better margins because the need for clearance sales is reduced. Good forecasting allows manufacturers to operate their production with lower capacity, time, and inventory buffers and to ensure the availability of pertinent raw materials and packaging materials further up the supply chain.

Forecasts are obviously important. In demand forecasting, it always makes sense to take advantage of low-hanging fruit. For instance, the investment will pay off if retailers do not yet make use of contemporary tools that enable them to automatically choose and use the most efficient combination of various time-series forecasting approaches and machine learning. On the other hand, it is also evident that demand projections will always be somewhat off, and that the planning process must take this into account.

In some circumstances, reducing the impact of forecast errors may simply be more cost-effective than spending money to further improve forecast accuracy. When it comes to inventory management, the cost of a modest increase in safety stock for a product with a long lifespan and shelf life may be quite affordable compared to the time demand planners would spend manually revising demand forecasts or fine-tuning forecasting models. Furthermore, any attempt to further improve forecast accuracy will be ineffective if the remaining forecast error is brought on by essentially random variation in demand.

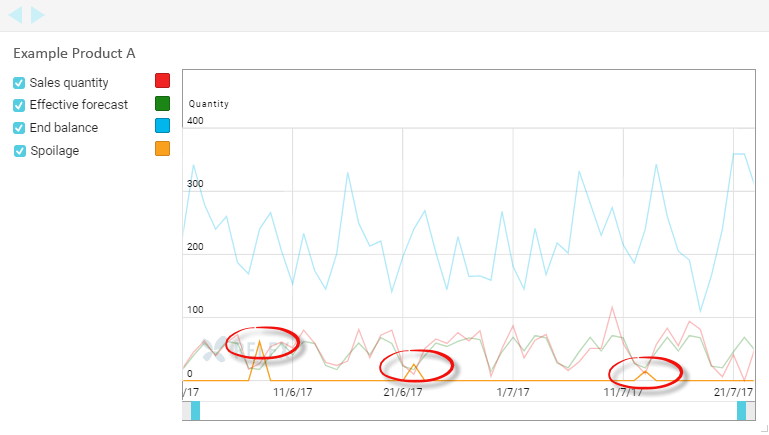

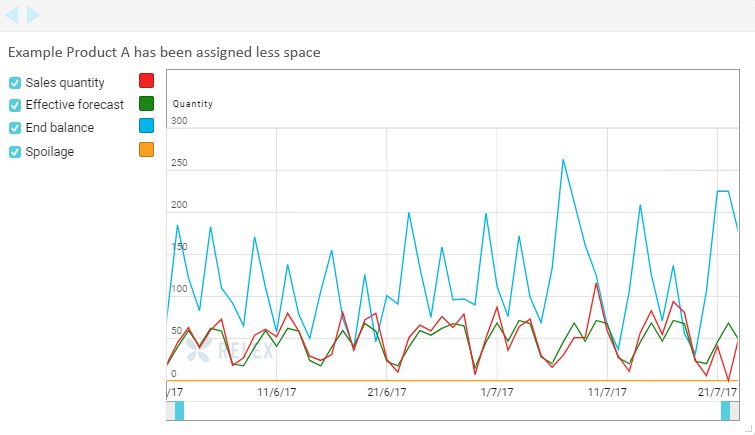

Beyond perfecting the demand forecast, there may be other factors that have a greater impact on the business outcome. For an illustration of how forecasting can be used to drive grocery store replenishment planning, see Figure 1. Although the example product and store’s forecast accuracy is quite good, systematic waste caused by product spoilage still exists. Further investigation reveals that the product’s presentation stock, i.e., packaging, is the primary offender responsible for the excessive waste. e. the quantity of inventory required to maintain an attractive display on its shelves. Without changing the forecast, the inventory levels can be pushed down to achieve 100% availability with no waste by allocating less space to the product in question (Figure 2).

The inference from the aforementioned instances is that even nearly perfect forecasts do not result in excellent business outcomes if the other phases of the planning process are not equally effective.

Forecasting is essential in some circumstances, such as the retail sale of fresh food. The use of advanced forecasting models, such as regression analysis and machine learning, for predicting the impact of promotions, cannibalization that may reduce demand for substitute items, and taking into account weather forecasts makes it economically prudent to invest in forecast accuracy. (Read more about predicting and replenishing fresh food supplies in our guide. ).

However, if batch sizes are too large or there is an excessive amount of presentation stock, all this work will be for nothing. Additionally, you must be able to dynamically adjust your safety stock per weekday when weekday sales variation is significant in order to minimize waste and maximize availability.

This, of course, holds true for any planning process. You will reach a point where further improvements in forecast accuracy will only slightly improve the actual business results if you only concentrate on forecasts and do not spend time on optimizing the other factors affecting your business results, such as safety stocks, lead times, batch sizes, or planning cycles.

Having a demand forecast

Having a demand or sales forecast is the first step. You may smile, but many companies don’t have one. Start with this equation if you don’t have one: average sales X seasonality X growth. You most likely already have forecasts if you use an ERP or other software.

I won’t delve any deeper into the topic of sales forecasting in this article because it is very broad. The best forecasting models for your entire supply chain will be provided by my “Forecasting Expert” program, which is still under development, if you have a specific need in this area.

If you absolutely must forecast in Excel immediately, take a look at my article, Forecasting in Excel in 3 Clicks: Complete Tutorial with Examples, where I outline simple techniques.

Biased and unbiased vs. accurate and less accurate forecasts

While some familiarity with both biased and unbiased forecasts is useful, it is insufficient. Additionally, it’s critical to comprehend the distinction between accurate and imprecise forecasts. The accuracy of your forecast determines how much of a difference there will be between it and your actual sales. A matrix can be created when bias and precision are combined. Obviously, the best result is an unbiased, highly precise forecast. The worst case is a biased, less precise forecast.

Try sales forecasting that is specially created to be as objective and accurate as possible if you and your business are sick of missing sales targets and keeping unsold inventory for months or even years. With more than 103 different forecasting techniques, including machine learning, deep learning, and the most cutting-edge AI technology, Inventoro is a free 14-day trial that will allow you to compare your sales forecasts to those generated by 21st-century technology.

FAQ

Why is it important to measure forecast error?

Reduce the risk of inaccurate forecasting in the future by using the forecast error calculation, which gives an evaluation of the precision of your previous projections. You can account for this risk in future forecasts if you can determine the degree of error in your earlier demand projections.

What does bias mean in forecasting?

When there is a consistent discrepancy between actual sales and the forecast, which may be due to over- or under-forecasting, bias is present in forecasting. Companies often measure it with Mean Percentage Error (MPE). If it’s positive, the bias is downward, which means the company tends to forecast too low.

Which of the following is best to measure bias in a forecast?

The arithmetic mean or expected value of the forecast errors is a common indicator of forecasting procedure bias, but other indicators of bias are also possible. A median-unbiased forecast, for instance, would be one where half of the forecasts are exaggeratedly high and half are exaggeratedly low: see Bias of an estimator.

Why is forecast accuracy important?

On the basis of recent and past data, forecasting enables businesses to set reasonable and quantifiable goals. Accurate data and statistics make it easier for businesses to determine how much change, improvement, or growth will be considered successful.