This sample Hazard Communication Program is provided by the Missouri On-Site Safety and Health Consultation Program. In order to comply with OSHA’s standard for Hazard Communication, 29 CFR 1910.1200, this written program must be site specific. Modify the template to reflect the policies and procedures at your company. Since OSHA regulations set minimum requirements, you may choose to add additional information to your site specific program. There is no requirement to follow this sample and its use does not guarantee compliance with the OSHA standard.

To ensure that information about the dangers of all hazardous chemicals used by (Name of Company) is known by all affected workers, the following Hazard Communication Program has been implemented. Under this program, workers will be informed of the requirements of the OSHA Hazard Communication Standard, the operations where exposure to hazardous chemicals may occur, and how workers can access this program, as well as labels and Safety Data Sheets (SDSs).

This program applies to any chemical which is known to be present in the workplace in such a manner that workers may be exposed under normal conditions of use or in a foreseeable emergency. All work areas that involve potential exposure to chemicals are part of the Hazard Communication Program. Copies of the Hazard Communication Program are available in the (Location) for review by any interested worker.

(Name of person or job title) is the program coordinator, with overall responsibility for the program, including reviewing and updating this program as necessary.

A list is attached to this program that identifies all hazardous chemicals with a potential for employee exposure at this workplace. Detailed information about the physical, health, and other hazards of each chemical is included in a SDS; the product identifier for each chemical on the list matches and can be easily cross-referenced with the product identifier on its label and on its SDS.

3. Safety Data Sheets (Name of Company) will obtain a SDS for each hazardous chemical from the distributor or supplier.

SDSs are readily available to all employees during their work shifts. Employees can review SDSs for all hazardous chemicals used at this workplace. (Identify the file location if they are stored in a paper file. Describe how to access them if they are stored electronically).

The SDSs are updated and managed by (Name of persons or job title responsible for managing SDS). If a SDS is not immediately available for a hazardous chemical, employees can obtain the required information by calling (Name of persons or job title responsible for providing information in an emergency).

SDSs for chemicals that are no longer actively used will be kept in an archived file for 30 years.

The labeling system to be used by (Name of Company) will follow the requirements in the 2012 revision of the OSHA Hazard Communication Standard and will be consistent with the United Nations Globally Harmonized System (GHS) of Classification of Labeling of Chemicals. The label on the chemical is intended to convey information about the hazards posed by the chemical through standardized label elements, including symbols, signal words and hazard statements.

(Name of persons or job title of employee managing container labeling)will ensure that all containers are appropriately labeled. No container will be released for use until this information is verified. Workplace labels will be legible and in English.

Small quantities intended for immediate use may be placed in a container without a label, provided that the individual keeps it in their possession at all times and the product is used up during the work shift or properly disposed of at the end of the work day.

Before they start their jobs or are exposed to new hazardous chemicals, employees must attend a hazard communication training that covers the following topics:

(Name of persons or job title responsible for managing the training program) is responsible to ensure that employees receive this training. After attending the training, employees will sign a form verifying that they understand the above topics and how the topics are related to our Hazard Communication Program.

Before employees perform special (non-routine) tasks that may expose them to hazardous chemicals, (Name of persons or job title) will inform them about the chemicals’ hazards. They also will inform them about how to control exposure and what to do in an emergency. The employer will evaluate the hazards of these tasks and provide appropriate controls including PPE and additional training as required.

Examples of special tasks that may expose employees to hazardous chemicals include the following:(include examples of special (non-routine) tasks).

Work activities may be performed by workers in areas where chemicals are transferred through unlabeled pipes. Prior to starting work in these areas, the worker shall be informed by (Name of persons or job title) about the identity and hazards of the chemicals in the pipe, as well as precautionary measures required to be followed.

If employees of other employer(s) may be exposed to hazardous chemicals at our workplace (for example, employees of a construction contractor working on-site), it is the responsibility of (Name of persons or job title) to provide contractors and their employees with the following information:

(Name of persons or job title) will also obtain a SDS for any hazardous chemical a contractor brings into the workplace.

Section 1, Identification includes product identifier; manufacturer or distributor name, address, phone number; emergency phone number; recommended use; restrictions on use.

Section 6, Accidental release measures lists emergency procedures; protective equipment; proper methods of containment and cleanup.

Section 8, Exposure controls/personal protection lists OSHAs Permissible Exposure Limits (PELs); Threshold Limit Values (TLVs); appropriate engineering controls; PPE.

Section 11, Toxicological information includes routes of exposure; related symptoms, acute and chronic effects; numerical measures of toxicity.

*Note: Since other Agencies regulate this information, OSHA will not be enforcing Sections 12 through 15 (29 CFR 1910.1200(g)(2)).

A hazard communication program commonly known as a hazcom program is a vital component of any workplace safety plan. Despite its importance, hazcom programs remain mysterious to many employees. This article will lift the veil of confusion surrounding hazard communication and provide a clear overview of what these programs entail.

What Exactly is a Hazard Communication Program?

A hazard communication program is a written plan that details how an employer will inform employees about the dangers of chemicals used in the workplace. The main goal is to ensure workers understand the risks so they can take steps to protect themselves.

The Occupational Safety and Health Administration (OSHA) requires virtually all companies using hazardous chemicals to implement a written hazcom program. It’s not just a nice extra – it’s mandated by law under OSHA’s Hazard Communication Standard 29 CFR 1910.1200.

At its core, a proper hazcom program enables employees to access information about chemical hazards and how to work safely around them. This knowledge is power when you’re dealing with substances that could potentially harm you

Key Elements of an Effective Hazcom Program

While the exact format may vary all hazcom programs should contain these core components

Chemical Inventory

A list identifying all hazardous chemicals present in the workplace. This inventory must be compiled for the program and updated as new chemicals are introduced.

Safety Data Sheets (SDS)

Formerly known as Material Safety Data Sheets (MSDS), these provide details about each hazardous chemical, including potential hazards and safety precautions. SDS must be readily accessible to employees.

Labels

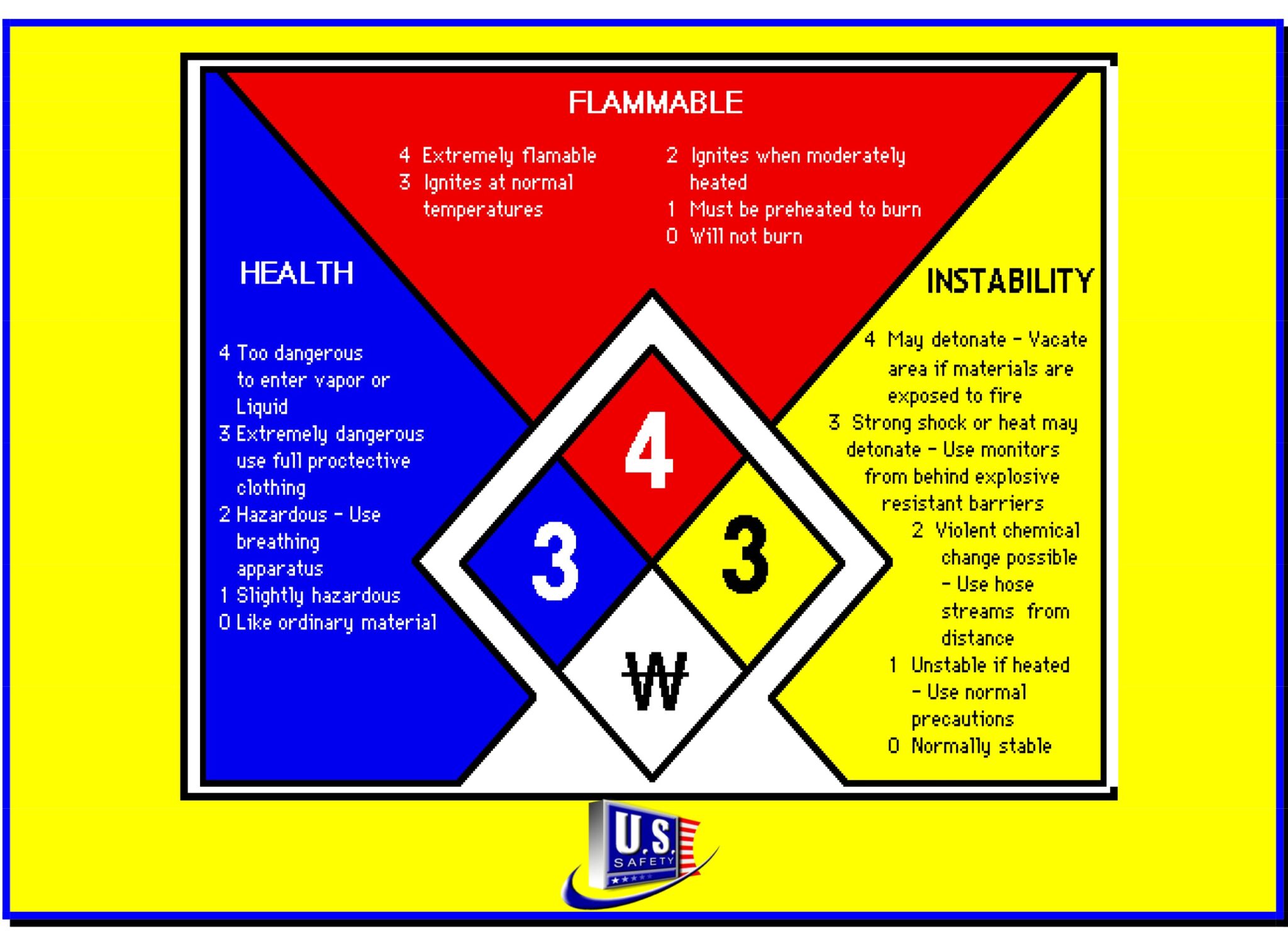

Containers of hazardous chemicals must display labels clearly identifying their contents plus hazard warnings. Labels alert employees to dangers at a glance.

Employee Training

Workers must receive training on hazcom program elements and chemical hazards they may face. Training should occur upon hire and whenever new chemicals are introduced.

Written Program

The written plan ties everything together, explaining how the company will maintain the inventory, share SDS, ensure proper labeling, train workers, and meet other requirements.

Which Chemicals Require a Hazcom Program?

The program must address any chemical posing a physical or health hazard. This includes, but is not limited to:

- Flammables, combustibles, compressed gases

- Carcinogens, toxins, irritants, corrosives

- Pesticides, chemicals used in manufacturing or construction

- Cleaning products, solvents, paints, adhesives

In other words, nearly any chemical with the potential to harm employees must be part of the hazcom program.

Which Employers Need a Hazcom Program?

If your company uses hazardous chemicals, chances are you need a hazcom program. The Hazard Communication Standard applies to all employers in the manufacturing sector. It also covers non-manufacturing employers if they have employees who may be exposed to hazardous chemicals under normal working conditions or during an emergency.

A few exceptions exist. For example, hazcom programs are not required for chemicals bound up in finished products like foods, drugs, or cosmetics. Programs are also unnecessary in retail trade establishments as long as employees only handle chemicals in sealed containers.

Outside of these narrow exemptions, most companies are legally obligated to implement and maintain a hazard communication program. Failing to do so puts employees at risk and exposes the employer to citations and penalties.

Benefits of a Well-Designed Hazcom Program

While hazcom programs are required by OSHA, they do far more than just keep companies in compliance. Effective programs have tangible benefits for your organization:

Improved Safety Culture – Openly communicating about chemical hazards fosters transparency and safety awareness. Employees take training to heart when they understand the true risks.

Informed Decisions – With access to SDS, workers can make smarter decisions about safe chemical use, storage, and disposal. Knowledge guides better safety practices.

Reduced Errors – Clearly labeled containers prevent mix-ups that could lead to dangerous errors. Workers know exactly what’s inside and how to handle it.

Lower Insurance – Insurers reward safe workplaces with lower premiums. Thorough hazcom programs demonstrate your commitment to risk reduction.

Prepared for Emergencies – Employees trained on chemical hazards and response procedures can react quickly and appropriately in an emergency.

Better Reputation – Consumers and partners want to work with safety-focused companies. Effective hazcom programs improve your reputation and attract business.

In short, hazcom programs not only satisfy legal requirements, they also cultivate a culture of safety that protects workers and the company as a whole.

OSHA Requirements for Written Hazcom Programs

OSHA expects hazcom programs to be clear, detailed, and customized to each workplace. At minimum, the written plan must spell out:

- List of all hazardous chemicals present

- Methods the company will use to inform employees of hazards, including labels, SDS, and training

- How the program will be updated as new chemicals are introduced

- Who is responsible for maintaining the program and related records

- How employees can access the written program and get more information

OSHA also requires the written program to be shared with employees upon request. This enables workers to double-check that all required elements are covered.

Consequences of Non-Compliance

Ignoring the Hazard Communication Standard has consequences. During inspections, OSHA inspectors will ask to see your written hazcom program and related records. Failure to provide these upon request often results in citations and fines.

Violations also increase the likelihood of chemical accidents and employee injuries. This leads to higher workers’ compensation costs, lawsuits, and damage to the company’s reputation.

In essence, skipping out on a hazcom program is never worth the risk. The financial, legal, and human costs are just too high.

Creating and Maintaining Your Hazcom Program

Here are some tips to create and maintain a compliant, effective hazcom program:

- Assign a program owner – Have one person responsible for keeping the program current

- Create a chemical inventory – Identify and list every hazardous chemical on site

- Collect SDS for each chemical – Maintain readily accessible binders

- Label everything – Use hazard warning stickers on all containers, large and small

- Document procedures – Detail how chemicals are received, stored, handled, and disposed

- Train employees – Conduct training for all exposed workers before exposure occurs

- Update constantly – Review the written plan and refresh training at least annually

With these core elements covered, your program will inform employees about chemical hazards at your unique workplace. Don’t look at it as just another regulation – a robust hazcom program is fundamental to safeguarding your most valuable asset, your employees.

Frequently Asked Questions About Hazard Communication Programs

Hazard communication programs protect employees, but they also raise common questions for both managers and workers. Here are answers to some of the top hazcom program FAQs:

Q: How often must hazcom training be conducted?

A: Initial training must occur before employees are exposed to hazards on the job. Refresher training should happen at least once per year and whenever new chemicals are introduced.

Q: Can hazcom training be conducted online?

A: Yes, OSHA allows web-based training as long as all program elements are thoroughly covered.

Q: Do part-time or temporary employees need hazcom training?

A: Yes, any employee with potential exposure to chemical hazards must be trained.

Q: Do cleaning chemicals require hazcom program coverage?

A: Yes, cleaning products contain hazardous chemicals so they must be inventoried, labeled, and addressed in training.

Q: Can electronic SDS binders replace paper copies?

A: Yes, electronic access is permitted as long as employees can get information when needed.

Q: How should containers be labeled?

A: Labels should include chemical names, hazard warnings, and manufacturer information.

Q: Does OSHA provide hazcom program templates?

A: No official templates exist. However, many sample programs are available online to use as a starting point.

Ensuring every employee understands these common FAQs will improve overall program effectiveness.

Partnering with Employees for Successful Programs

For maximum safety, employers should view employees as partners, not just participants, in the hazcom program. Encouraging involvement creates buy-in. Consider these tips:

-

Invite employees to assist in developing training content. They know firsthand which topics need emphasis.

-

Ask for input about existing safety processes. Tap frontline experience to improve procedures.

-

Share success stories highlighting how the program prevented incidents. This drives home the value.

-

Consider forming a safety committee with employee representatives. This fosters ongoing engagement.

-

Recognize outstanding safety performance. Find creative ways to reward diligence and vigilance.

Remember, informed and empowered employees are in the best position to protect themselves day to day. Partner with them to nurture a culture of openness, ownership, and hazard awareness.

Hazard Communication Programs Save Lives

Workplace incidents can change lives in an instant. But knowledge and preparation can help avoid tragedies altogether. Hazard communication programs buil