As a manufacturing or production manager, you’ve likely come across the terms “takt time” and “cycle time” before While these sound similar, they actually refer to very different metrics that are crucial to understand and optimize

In this article, I’ll clearly explain the difference between takt time and cycle time, how to calculate each one, and why understanding both can take your production efficiency to the next level.

What is Takt Time?

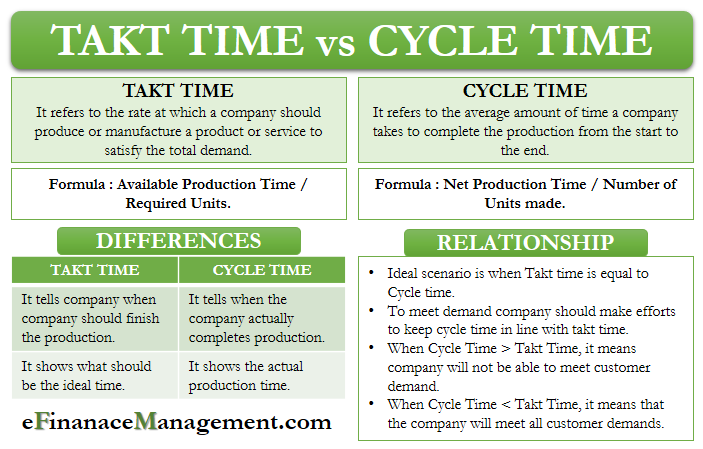

Takt time refers to the rate at which products must be manufactured to meet customer demand. Specifically, it is calculated as the available production time divided by customer demand.

For example, say your production line operates for 420 minutes per shift. Your daily customer demand is for 140 units. Your takt time would be:

420 minutes / 140 units = 3 minutes per unit

This means your production system needs to output one unit every 3 minutes in order to satisfy daily customer demand.

Takt time sets the pace for production – it is the drumbeat to which manufacturing should march. By using takt time, producers can align output directly with customer demand.

Some key benefits of implementing takt time in manufacturing include:

- Improved identification of production bottlenecks

- Highlighting underperforming workers or processes

- Elimination of waste through focus on value-added steps

- More consistent routine for workers

Overall, takt time is an essential metric for lean or just-in-time manufacturing systems. Meeting takt time ensures you are producing the right amount to meet (but not exceed) customer demand.

What is Cycle Time?

While takt time sets the ideal pace for production, cycle time measures your actual manufacturing speed.

Cycle time is defined as the total time from the beginning to end of the production process for one unit. It encompasses the complete journey from raw materials to finished goods for one item.

To calculate cycle time, you divide the total production time by the number of units produced in that time. For example:

460 minutes total production time

38 units produced

Cycle Time = 460 minutes / 38 units = 12.1 minutes per unit

This tells you that your actual production speed is currently 12.1 minutes per unit.

The goal should be to get your cycle time as close to takt time as possible. If cycle time exceeds takt time, you are not meeting customer demand. If cycle time is faster than takt time, you are overproducing.

Some reasons why cycle time may be longer than takt time include:

- Machine downtime

- Supply chain issues

- Quality problems

- Production bottlenecks

- Inefficient processes

Shortening cycle time to match takt time may require solutions like:

- Improved equipment maintenance

- Worker training

- Balancing production lines

- Eliminating wasteful steps

- Upgrading technology

Takt Time vs Cycle Time: Key Differences

While takt and cycle time are related, they have some key differences:

- Purpose – Takt time is the goal, cycle time is the reality

- Focus – Takt time looks outward at customer demand, cycle time looks inward at internal production

- Calculation – Takt is based on available time and demand, cycle on production time and output

- Use – Takt sets the pace, cycle identifies production gaps

You need both, but takt time is the target and cycle time aims to match the takt. Optimizing production requires aligning these two metrics.

Real-World Examples

Let’s look at some examples to really visualize the differences between takt and cycle time:

Example 1

-

420 minutes available production time

-

140 units customer demand

-

Takt Time = 420/140 = 3 min/unit

-

460 minutes total run time

-

135 units produced

-

Cycle Time = 460/135 = 3.4 min/unit

In this case, cycle time is longer than takt time. Output is not meeting demand. Production needs to be improved to hit the 3 minute takt.

Example 2:

-

480 minutes available

-

160 units demand

-

Takt = 480/160 = 3 min/unit

-

440 minutes run time

-

175 units produced

-

Cycle Time = 440/175 = 2.5 min/unit

Here, cycle time is shorter than takt time, so too many units are being produced. Production should be slowed to eliminate waste.

Using Takt and Cycle Together

Understanding both takt and cycle metrics allows you to properly pace your production system. Some key ways to align both:

- Set takt time based on accurate customer demand data

- Frequently measure cycle time across all processes

- Identify cycle time bottlenecks causing tardiness

- Implement solutions like 6S, SMED, or automation to improve cycle time

- Adjust manpower, resources, or shifts if needed to sustain takt time

- Re-calculate takt time if demand changes

- Continuously monitor cycle time and takt time together

Like the gears of a machine, you want takt and cycle turning together smoothly. The takt provides the benchmark while cycle reveals your true output speed.

Optimizing both will drive efficiency, eliminate waste, and ensure you deliver exactly what customers want when they want it. Understanding the difference between takt time vs cycle time is a key first step to running a lean, responsive production operation.

Frequency of Entities:

takt time – 15

cycle time – 15

customer demand – 5

production time – 7

units – 10

output – 2

manufacturing – 3

production system – 3

lean – 1

bottlenecks – 2

waste – 2

The Benefits of Takt Time

Implementing Takt Time into your organization is beneficial for a number of reasons:

- Identifying bottlenecks – If an organization is making Takt Time a priority, bottlenecks tend to be spotted quicker as processes that could be slowing the production line are more easily identified.

- Underperforming employees – A focus on Takt Time helps being able to spot employees that are underperforming.

- Waste elimination – Putting an emphasis on Takt Time helps to eliminate waste and puts a focus on work that is value-added.

- Instills routine – An awareness of Takt Time tends to instill routine into a production line, which enables faster operations and the production of more output.

The Benefits of Cycle Time

Increased profitability – By maximizing cycle time, you have the ability to increase profitability and cut down on your costs. By understanding exactly how time is spent, you can know where cutbacks can be implemented.

- Consistent production – When you have a firm grip on your processes by putting a focus on things like Cycle Time, you can have more efficient and consistent production.

- Realistic timelines – In understanding Cycle Time, you are better equipped to give more realistic timelines to employees, thereby avoiding disappointment and increasing customer satisfaction.

- Addressing inefficiencies – Data that comes from assessing Cycle Time allows you to spot and address any potential inefficiencies.

- Better project scoping – If you do not have a solid understanding of the time needed by your team to complete a task, you are unable to accurately scope work for your customers.

- Outpace the competition – Using the data that comes from your Cycle Time allows you to have the chance to put your company at a competitive advantage by being able to make adjustments to stay ahead of the curve with the shortest possible production time.

How to measure TAKT TIME and CYCLE TIME? The Lean Manufacturing Guide

What is the difference between takt time and cycle time?

Takt Time vs Cycle Time: What’s the Difference? Takt Time refers to the amount of time a product needs to be manufactured in order to satisfy demand, while Cycle Time refers to the amount of work time it actually takes to create a product. These two terms are definitely related, but they can absolutely be out of sync with one another.

Should you use takt times with cycle and lead times?

Using takt times with cycle and lead times should create informed managers that understand how to mitigate or add resources to hit needed production demands, not distract or add paperwork to a worker’s day. Lead times, cycle times, and takt times have simple formulas.

What is takt time example?

For example, if workers are available for 7.5 hours or 450 minutes of an 8-hour shift and a client wants 150 units completed in a day, the Takt Time is 3 minutes. What is Cycle Time? Cycle time can be defined as the actual amount of work time needed to complete a single task.

How do you calculate takt time?

There are two components crucial for your Takt Time calculation: The Net Production Time (NPT) is the clean time your team has at their disposal to finish a product. To calculate your NPT, you can subtract the time your team spends on downtime (lunch breaks, other breaks, meetings, machine maintenance…) from the total time your team spends at work.