Landing a job as a chemical process engineer requires you to demonstrate extensive technical expertise as well as strong communication and problem-solving skills. The interview is your chance to prove to recruiters that you have what it takes to handle the complex responsibilities of optimizing chemical manufacturing processes

This comprehensive guide will equip you with insights on the most common chemical process engineer interview questions along with tips on how to ace your responses.

Why Do You Want To Be A Chemical Process Engineer?

This question aims to gauge your passion and motives for pursuing this career path Interviewers want to know what drives your interest

In your response, focus on conveying your enthusiasm for the field. Share how you find the work meaningful and aligned to your talents. You could mention:

-

A lifelong fascination with chemistry and solving technical problems.

-

Enjoying process optimization challenges and continuous improvement projects during internships.

-

Finding satisfaction in making production processes safer, more efficient, and environmentally sustainable.

Explain The Difference Between A Unit Operation And A Unit Process

This tests your fundamental knowledge of core concepts in chemical engineering. Unit operations involve physical processes like heat transfer, mass transfer, and separations. Unit processes focus on chemical transformations.

In your answer, provide definitions of each term. Give examples like distillation as a unit operation and polymerization as a unit process. Emphasize how unit operations and processes are combined in the overall manufacturing of chemicals.

Describe Your Understanding Of Process Safety

Safety is paramount in chemical process engineering. Interviewers want reassurance that you thoroughly grasp safety principles and will proactively minimize risks.

In your response, convey:

-

Awareness of hazards like toxicity, flammability, runaway reactions.

-

How to perform safety analyses like HAZOP to identify risks.

-

Mitigation strategies like fail-safe controls, protective equipment, training.

-

The importance of a safety-first mindset and not taking shortcuts.

How Do You Handle Hazardous Chemicals In A Plant?

This evaluates your practical knowledge of safety protocols when working with hazardous substances. Recruiters want to see that you understand and follow all necessary precautions.

In your answer, highlight:

-

Wearing appropriate PPE like chemical-resistant clothing, gloves, goggles.

-

Following established handling and storage procedures.

-

Understanding MSDS and risks like corrosion, explosions.

-

Ensuring equipment like fume hoods and Eyewash stations are accessible.

-

Disposing of waste properly and decontaminating after handling.

What Are The Most Important Aspects Of Process Design?

This tests your end-to-end understanding of the key factors involved in designing efficient and safe chemical processes.

In your response, convey that you consider:

-

Process chemistry fundamentals like reaction kinetics, yields.

-

Thermodynamic factors like phase equilibria, heat integration.

-

Mechanical elements like pumps, compressors, reactors.

-

Process control systems and instrumentation.

-

Safety features like pressure relief valves, containment.

-

Environmental regulations, waste minimization, and sustainability.

Explain How You Would Troubleshoot A Process Bottleneck

This demonstrates your systematic problem-solving abilities when faced with production issues. Recruiters want to understand your thought process in debugging and optimizing processes.

In your answer, highlight steps like:

-

Gathering data on process conditions and performance history.

-

Identifying potential causes through process analysis.

-

Using investigative tools like tracer tests to isolate issue.

-

Modifying process variables like temperature, pressure, flow rates.

-

Considering equipment upgrades or re-design if needed.

-

Implementing long-term process controls to prevent recurrence.

How Do You Ensure A Process Is Safe And Environmentally Compliant?

This tests your knowledge of process safety management and environmental regulations. Interviewers want to know that you can proactively address risks and meet all legal standards.

In your response, discuss:

-

Conducting rigorous hazard analyses like HAZOP.

-

Incorporating engineering and procedural controls like alarms, interlocks.

-

Implementing requirements like emissions monitoring and waste treatment.

-

Performing safety reviews and audits, training workers on protocols.

-

Staying current on changing environmental regulations.

Can You Optimize This Distillation Column Design?

Distillation questions evaluate your technical abilities and problem-solving skills through a hands-on exercise. The interviewer may provide process conditions and ask you to improve efficiency and throughput.

As you walk through your approach, highlight steps like:

-

Reviewing specifications like feed composition, product purity.

-

Considering options like adding trays, adjusting reflux ratio and boilup rate.

-

Discussing tradeoffs like capital costs versus operating costs.

-

Calculating the impact of changes through mass/energy balances.

-

Justifying your recommendations with technical data.

How Do You Handle Changing Raw Material Feedstocks?

This assesses your adaptability in dealing with variable or inconsistent inputs – a common challenge in real-world settings. Interviewers want to see how you adjust processes to maintain quality and yield.

Emphasize consistently monitoring feedstock properties through testing. Describe how you would modify process conditions and equipment parameters to accommodate variability. Provide an example where your troubleshooting and optimization skills overcame input fluctuations.

Describe A Time You Solved A Complex Technical Problem

Behavioral questions allow you to showcase transferable skills and thought processes critical to succeeding as an engineer. This example demonstrates analytical abilities and perseverance when overcoming obstacles.

Choose a technical accomplishment that highlights strengths like:

-

Methodical data gathering and root cause analysis.

-

Creativity in developing solutions.

-

Leadership in collaborating with cross-functional teams.

-

Tenacity in the face of setbacks during implementation.

-

Continuous improvement mindset.

How Do You Stay Current In The Field Of Chemical Engineering?

Ongoing learning is essential in this rapidly evolving profession. Recruiters want candidates who proactively enrich their expertise and remain up-to-date on technological advancements.

To convey your commitment, discuss activities like:

-

Reading industry publications and journals.

-

Attending conferences and seminars.

-

Taking continuing education courses.

-

Joining professional organizations like AIChE.

-

Experimenting with new modeling and simulation tools.

Why Should We Hire You Over Other Candidates?

This closing question provides a chance to summarize your strongest qualifications and unique value proposition.

Tailor your response based on the role’s requirements, while conveying:

-

A proven record of optimizing processes and delivering results.

-

Specific skills and expertise in areas critical to the position.

-

Strong technical knowledge combined with problem-solving abilities.

-

Passion for continuous learning and professional development.

-

Interpersonal and communication skills to collaborate cross-functionally.

With preparation and practice, you can ace your chemical process engineer interview. Use these questions to understand areas of assessment and come up with compelling stories and examples that highlight your capabilities. Combine technical depth with enthusiasm, and you’ll be ready to take on exciting new challenges in this dynamic field.

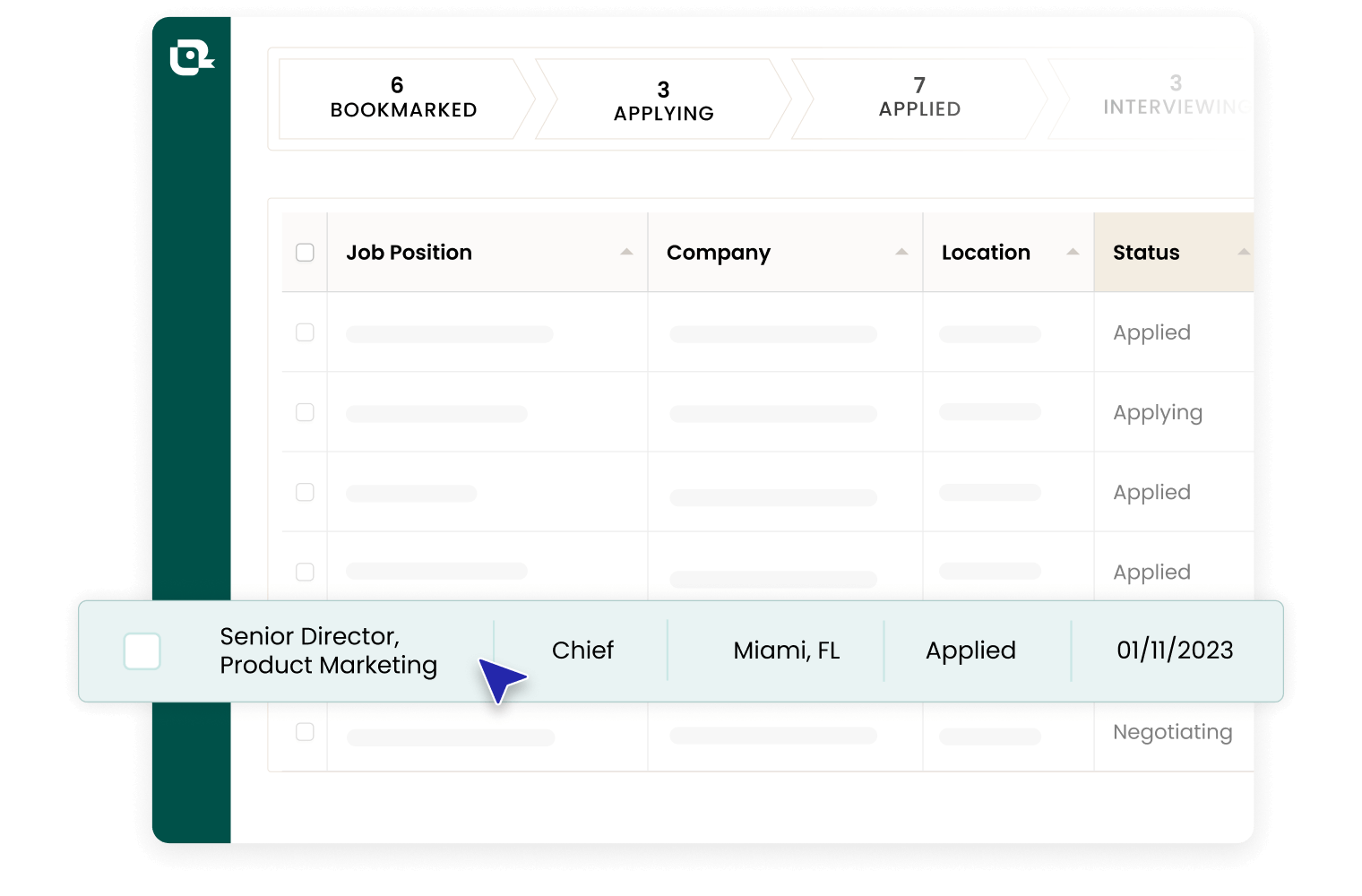

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Interviewing as a Process EngineerEmbarking on the journey to secure a role as a Process Engineer involves navigating through a series of interviews that test not only your technical expertise but also your analytical thinking and problem-solving skills. Process Engineers are the backbone of operational efficiency, and their interviews reflect the multifaceted nature of their responsibilities. In this guide, we’ll dissect the array of questions that you, as a Process Engineer candidate, should anticipate. From probing your understanding of process design and optimization to evaluating your ability to manage projects and work collaboratively across departments. We’ll provide you with the tools to craft compelling responses, share insights on the hallmarks of an exceptional candidate, and suggest strategic questions to pose to your potential employers. Our aim is to arm you with the knowledge and confidence required to excel in your interviews and propel your career forward as a Process Engineer.

- Review Core Engineering Principles: Go over basic engineering ideas like thermodynamics, fluid mechanics, and material science again. These are often the basis for technical questions.

- Learn About the Company’s Products and Processes: Find out about the company’s manufacturing methods, the products they make, and the problems they face in their industry. This will let you make your answers fit the situation.

- Learn About Useful Process Engineering Software and Tools: Get to know process simulation software and tools like HYSYS, Aspen Plus, or MATLAB that are commonly used in the field, and be ready to talk about how well you know how to use them.

- To get ready for behavioral questions, think about projects and situations from the past where you used your process engineering skills. Get ready to talk about these events and what you learned from them.

- Learn more about project management and lean principles. Process engineers work on a lot of projects that need good management and lean operations. It can be very helpful to know about project management frameworks and lean methodologies.

- Put together a portfolio of your work. If you can, bring examples of your work, like process diagrams, P

- Prepare Thoughtful Questions: Write down some questions that show you’re interested in the company’s upcoming projects, process problems, and what they expect from you in this role.

- Do mock interviews. Work on your ability to communicate your ideas clearly and professionally by practicing with a friend or mentor. This can also help alleviate interview anxiety.

By following these steps, youll be able to enter the interview with confidence in your abilities and a clear understanding of how you can contribute to the companys objectives. Remember, the goal is not just to answer questions, but to engage in a dialogue that positions you as a valuable asset to the team.

Chemical & Process Engineering Interview Preparation | How to Prepare for the Technical Interview?

FAQ

How to crack a chemical engineering interview?

What is the role of a process engineer in chemical engineering?

What questions should a chemical engineer ask?

Technical questions are the cornerstone of a Chemical Engineer’s interview, as they assess your core knowledge of chemical processes, engineering principles, and industry-specific technologies. Expect to answer questions on thermodynamics, reaction kinetics, process design, and safety protocols.

What is a chemical process engineering interview?

This question is designed to assess your hands-on experience and problem-solving skills in the field of chemical process engineering. It gives interviewers insight into your thought process, creativity, and understanding of chemical processes.

What is a chemical engineer interview question?

This question allows the interviewer to gauge your level of experience with the technical aspects of the job. Chemical engineers are expected to be able to create and optimize chemical processes, so the interviewer is looking for evidence that you have the skills to do this.

Does a chemical process engineer have the technical knowledge required?

This question is posed to assess whether you possess the technical knowledge and experience necessary for this particular role. The production of polymers involves complicated chemical processes, and it’s critical that a chemical process engineer has a robust understanding of these.