Getting hired as a bioprocess engineer is no easy feat. You’ll need to demonstrate deep knowledge across biology, engineering, and bioprocessing to land the role. That’s why it’s essential to come prepared for the interview with clear, compelling responses to common bioprocess engineer interview questions.

This guide has everything you need to know about the 27 most common and important interview questions for bioprocess engineering candidates. I will give you examples of good answers as well as advice and suggestions to help you write your own. Let’s dive in!.

1. What experience do you have with cell culture technology?

Cell culture is the backbone of bioprocess engineering, so interviewers want to know you have hands-on experience. In your response, demonstrate your proficiency working with mammalian, microbial, and other cell cultures. Discuss your expertise in optimizing growth conditions, maintaining sterility, monitoring cell health, and troubleshooting contaminations. Highlight specific techniques like operating bioreactors and experience with process scale-up.

2. Walk me through a time you designed, validated, and implemented a new bioprocess.

With this question, interviewers want to see your capacity for critical thinking, creativity, and problem-solving Respond by outlining a specific example such as optimizing recombinant protein production through process redesign Discuss how you leveraged design of experiments (DOE) to enhance yield and validated the process at small scale prior to implementation. Emphasize how your systematic approach led to tangible improvements.

3. How would you optimize a bioprocess for cost-effectiveness and efficiency?

Demonstrate your technical expertise in bioprocess optimization here. Discuss strategies like improving microbial/cell line productivity through genetic engineering, optimizing downstream processing to reduce costs, and implementing advanced technologies like continuous manufacturing. Also highlight approaches for minimizing waste and leveraging byproducts.

4. Tell me about a time you had to troubleshoot a bioprocess system.

Use a specific example to showcase your analytical abilities and problem-solving skills. Explain how you isolated the issue through root cause analysis, implemented corrective actions, and took steps to prevent future occurrences. Emphasize quick thinking, effective communication, and documentation.

5. How do you ensure compliance with regulatory standards in your work?

Highlight your deep understanding of relevant regulations and your commitment to compliance. Discuss how you adhere to protocols through training, process validation, documentation, and self-auditing. Demonstrate how you stay current on regulatory changes and foster a culture focused on standards.

6. Describe your experience with bioreactor operation and optimization.

Provide an overview of your hands-on expertise with bioreactor systems for both batch and continuous processes. Discuss how you leveraged DOE and other tools to optimize productivity and yield. Give examples of troubleshooting issues like foaming or contamination. Convey your broad experience spanning process types, scales, and challenges.

7. Explain a time you used statistical analysis to improve a bioprocess.

Give an example of how you collected data, used regression analysis to find the most important factors affecting output, and then used a DOE approach to make conditions better. Highlight how your data savvy analytical skills directly enhanced process efficiency.

8. What is your approach for developing and implementing standard operating procedures (SOPs)?

Convey your understanding of mapping processes, identifying risks, and creating easy-to-follow, compliant protocols. Emphasize the importance of staff training on procedures and performing regular audits. Discuss how you continuously improve SOPs based on feedback and process changes.

9. Explain a time you worked cross-functionally to achieve a bioprocess objective.

Use an example like collaborating across departments to balance conflicting priorities. Talk about how communicating and analyzing data to get stakeholders from different functions to work together led to the best solution. Demonstrate your ability to see the bigger picture.

10. Describe your experience with downstream processing and purification.

Highlight your specialized expertise in key techniques like chromatography, filtration, and centrifugation. Provide examples of how you designed and optimized downstream processes for maximum purity and yield. Convey your proficiency in process scale-up, modeling, data analysis, and troubleshooting.

11. How have you ensured safety and quality control in previous roles?

Discuss your multifaceted approach through SOP adherence, equipment checks, data monitoring, training, and regulatory compliance. Emphasize proactive prevention, auditing, and fostering a quality-focused culture. Demonstrate how your efforts systematically minimized risks.

12. How do you approach scaling up a bioprocess?

Showcase your understanding of critical parameters and using modeling/simulations to predict scale-up challenges. Discuss verifying designs at pilot scale prior to manufacturing implementation. Highlight the importance of risk management, troubleshooting, and optimization during scale-up activities.

13. What strategies have you used to improve yield and productivity?

Provide overview of techniques you’ve applied like DOE, statistical process control, metabolic engineering, continuous processing, etc. Give examples of how you’ve leveraged these strategies to achieve tangible improvements for specific bioprocesses.

14. Explain a time you used process simulation software to model a bioprocess.

Use a specific example like optimizing protein production through modeling with SuperPro Designer. Take the interviewer through how you input parameters, ran simulations, and identified optimal conditions. Highlight how this improved process efficiency and reduced costs.

15. How would you handle a bioprocess not meeting performance metrics?

Convey a structured approach focused on root cause analysis, developing an action plan, and communicating with stakeholders. Emphasize implementing solutions aligned to the specific process and issue identified through thorough analysis.

16. Describe your experience with process validation and equipment qualification.

Demonstrate hands-on experience by providing examples of executing process qualification runs and qualifying equipment through activities like IQ, OQ, and PQ. Highlight your use of statistical tools and data-driven mindset when qualifying processes and equipment.

17. How do you approach developing and maintaining process documentation?

Discuss how you thoroughly map processes, identify risks, and collaborate with teams when developing documents. Emphasize the importance of regularly reviewing and updating documentation to ensure accuracy as processes evolve.

18. What is your experience with technology transfer of bioprocesses?

Highlight expertise in ensuring reproducibility, managing risk, and effective planning/communication when transferring tech between sites. Provide an example and discuss how you applied troubleshooting skills to handle equipment/scale differences.

19. Tell me about a time you implemented new technologies into a bioprocess.

Use a specific example like integrating a new chromatography system. Discuss your process of reviewing current process, planning change management, training staff on new tech, and monitoring after implementation. Demonstrate thoughtful integration without disrupting ongoing operations.

20. How do you handle unexpected results or anomalies in a bioprocess?

Emphasize root cause analysis, implementing corrective actions, and proactive prevention. Discuss adjusting parameters, replacing equipment, and modifying protocols in response to a specific situation. Convey a mindset of continuous improvement.

21. Explain a situation where you applied cell/biochemical principles to solve a bioprocess problem.

Use a case where fundamental scientific knowledge was key to finding a practical solution. For example, adjusting culture medium composition by applying cell biology principles to maintain plasmid stability and improve protein expression.

22. What is your approach to training others on bioprocess procedures?

Convey a structured approach focused on theory, demonstrations, practice sessions, and ongoing support. Discuss the importance of using visual aids, encouraging questions, and providing feedback. Highlight regular assessments to gauge progress and identify knowledge gaps.

23. How have you applied Good Manufacturing Practices (GMP) in previous roles?

Provide examples of how you upheld GMP in areas like documentation, process validation, staff training, and self-auditing. Discuss how your efforts enhanced product quality, safety, and regulatory compliance.

24. Describe conducting a risk assessment for a bioprocess.

Provide a specific example like using FMEA to assess contamination, equipment failure, and parameter deviation risks during a scale-up project. Discuss evaluating and prioritizing risks and developing mitigation strategies like redundant systems and enhanced monitoring.

25. How have you used project management skills in bioprocess engineering?

Discuss examples like coordinating resources, managing schedules, and monitoring milestones when optimizing a bioreactor. Emphasize how skills like planning, problem-solving, adapting to change, and delivering results were key to project success.

26. What sustainability strategies do you implement in bioprocesses?

Demonstrate commitment to sustainability by highlighting approaches you’ve applied like energy efficiency optimization, waste minimization, and renewable resource utilization. Provide examples of how you’ve balanced productivity with environmental responsibility.

27. Describe working under pressure to meet a deadline in a bioprocess project.

Use an example to convey your ability to manage competing priorities and deliver results in high-pressure scenarios. Discuss how you remained focused, leveraged your technical skills, and used communication to drive outcomes under a tight deadline.

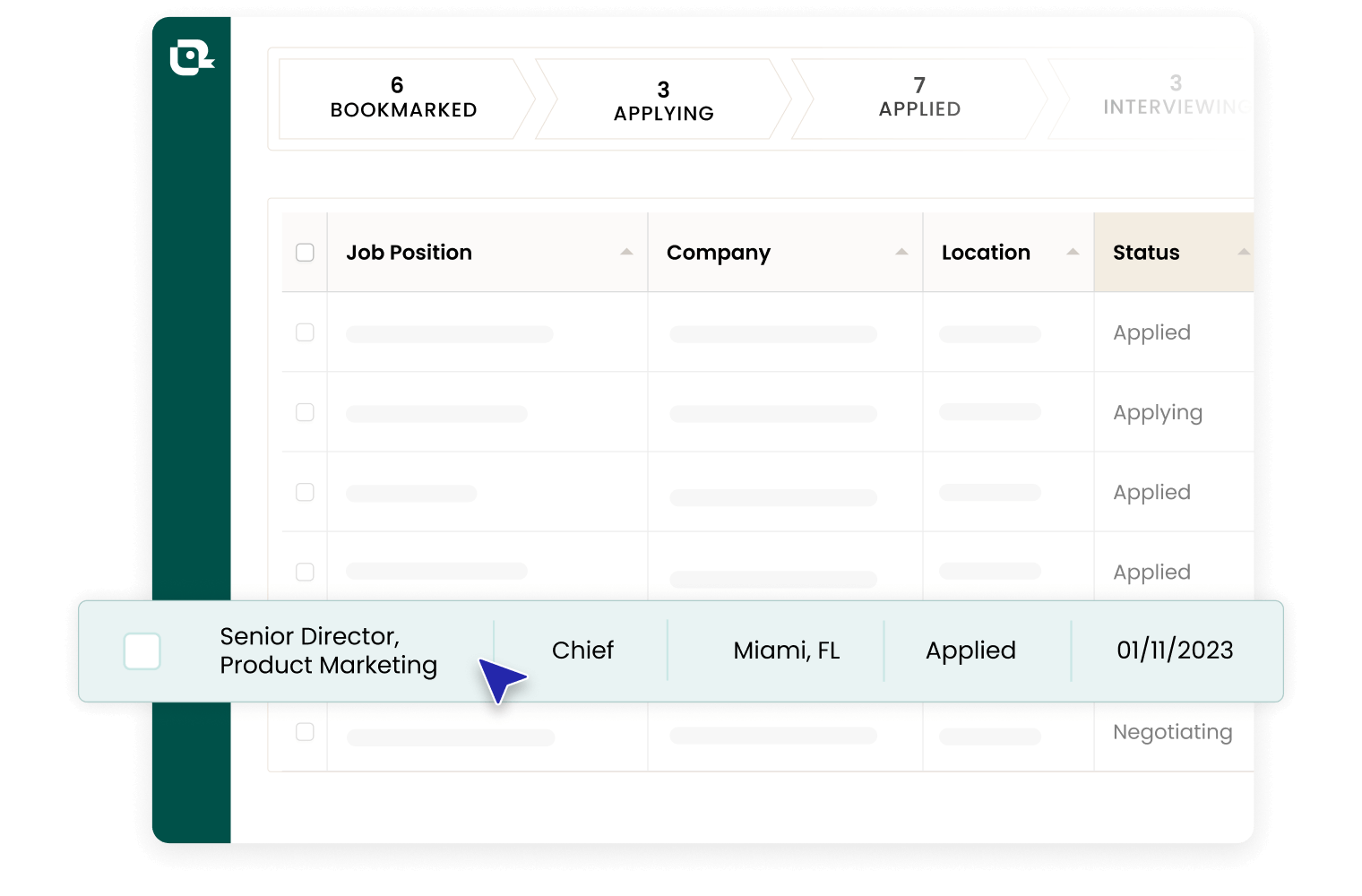

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Interviewing as a Process EngineerEmbarking on the journey to secure a role as a Process Engineer involves navigating through a series of interviews that test not only your technical expertise but also your analytical thinking and problem-solving skills. Process Engineers are the backbone of operational efficiency, and their interviews reflect the multifaceted nature of their responsibilities. In this guide, we’ll dissect the array of questions that you, as a Process Engineer candidate, should anticipate. From probing your understanding of process design and optimization to evaluating your ability to manage projects and work collaboratively across departments. We’ll provide you with the tools to craft compelling responses, share insights on the hallmarks of an exceptional candidate, and suggest strategic questions to pose to your potential employers. Our aim is to arm you with the knowledge and confidence required to excel in your interviews and propel your career forward as a Process Engineer.

- Review Core Engineering Principles: Go over basic engineering ideas like thermodynamics, fluid mechanics, and material science again. These are often the basis for technical questions.

- Learn About the Company’s Products and Processes: Find out about the company’s manufacturing methods, the products they make, and the problems they face in their industry. This will let you make your answers fit the situation.

- Learn About Useful Process Engineering Software and Tools: Get to know process simulation software and tools like HYSYS, Aspen Plus, or MATLAB that are commonly used in the field, and be ready to talk about how well you know how to use them.

- To get ready for behavioral questions, think about projects and situations from the past where you used your process engineering skills. Get ready to talk about these events and what you learned from them.

- Learn more about project management and lean principles. Process engineers work on a lot of projects that need good management and lean operations. It can be very helpful to know about project management frameworks and lean methodologies.

- Put together a portfolio of your work. If you can, bring examples of your work, like process diagrams, P

- Prepare Thoughtful Questions: Write down some questions that show you’re interested in the company’s upcoming projects, process problems, and what they expect from you in this role.

- Do mock interviews. Work on your ability to communicate your ideas clearly and professionally by practicing with a friend or mentor. This can also help alleviate interview anxiety.

By following these steps, youll be able to enter the interview with confidence in your abilities and a clear understanding of how you can contribute to the companys objectives. Remember, the goal is not just to answer questions, but to engage in a dialogue that positions you as a valuable asset to the team.

TOP 10 Questions Asked in Biotech Interview + How To Answer Them?

FAQ

What is your greatest weakness as an engineer?